Introduction to RAM Models and Criticality Analysis

Building a Reliability, Availability and Maintainability (RAM) model can provide numerous benefits to an Asset Management program. This includes conducting a Criticality Analysis. Criticality Analysis involves ranking assets based on their potential risk to the organization. It considers risk categories such as Production Impact, Safety, Environment, and Reputation, amongst others. The category list can vary and is a reflection of the organization’s structure. Organizations generally have a finite financial pool allocated to preserving asset function. A Criticality Analysis helps optimize the allocation of resources to each asset according to its importance in the system network. Ultimately this helps maximize revenue, minimize spend and maintain the organization’s license to operate.

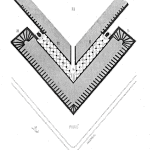

The fundamental purpose of RAM modeling is to quantify system performance. Typically in a future time interval. A system is a collection of items that, when operated in coordination, generates an output. This output is typically a production value. For example, the number of widgets factory X expects to “realistically” produce in the next 5 years. The system includes subsystems, components, software, human operations, and more. An automobile as in Diagram 1, is a system. With automobile subcomponents such as the drive train, engine, gearbox, etc. In RAM models, it is crucial to account for relationships between these subcomponents. This in order to determine the final output of the system. For the automobile, that output could be:

- How far will the automobile travel before seeing a failure?

- How many failures will it see in its lifetime?

- How much will maintenance and repairs cost in the automobile’s lifetime?

RAM models have proven to be effective tools for cost avoidance and decision-making. The model can also confirm or help challenge assumptions made by internal stakeholders.

Criticality and Risk Calculations

A Criticality Analysis is based on risk calculations. Risk is the product of an event’s probability and its consequence. Therefore, if pump XYZ has a high probability of failure and leads to major production interruption, it will likely end up at the top of the criticality list. As a critical asset, it will require more resources to prevent or address failures.

While the risk equation appears to be simple, it can sometimes be problematic. The “failure likelihood” is used in lieu of a statistically derived probability. This likelihood is the simple average of event occurrences over a defined time span. In the case of pump XYZ, it failed 10 times in ten years so the likelihood of failure is 1 failure per year. However, in reality, an equipment’s failure occurrences may vary over its lifetime. Like an automobile experiencing an increase in failure frequency toward the end of its life. Additionally, when conducting a risk calculation for a system composed of interconnected equipment subsystems, it is important to consider the interconnectivity or dependency of each component. Traditional risk analysis often looks at individual equipment in isolation. This can lead to incorrect results and a flawed Criticality Analysis.

By taking into account the system network and all its connections, a RAM model provides a better overview of the system’s risk. The model also incorporates the operating philosophy of the system. This refers to different operational modes occurring over time. Such as seasonal production changes, redundant equipment coming online, or process upsets leading to flow bypasses or reductions, amongst others. The model can also identify a bottleneck in the system. Also known as a single point vulnerability. The model can specifically quantify the impacts generated by this bottleneck.

The life statistics or life distributions provided for each component (or block) in the model reflect the true changes over time, especially equipment deterioration. Ultimately, at a high level or precisely at a system level, the output of the RAM model itself represents a risk calculation. It combines the network’s life performance with the consequences of that performance on production output.

Limitations of a RAM model in Criticality Analysis

As mentioned earlier, the risk category best quantified by the RAM model is Production Impact. When it comes to the criticality list, the RAM model accurately assesses each individual equipment’s contribution to the overall production value. For example, if the network model includes 1,000 equipment units, a pareto chart with 1,000 relative impact rankings can be generated. This reflects the equipment criticality classification in terms of this specific production risk category. Production Impact is only one risk category in a Criticality Analysis. The RAM model does not directly account for the other risk categories such as safety, environmental or reputational impacts.

Nevertheless, once the RAM model is constructed, a significant portion of requirements to evaluate other risk categories is made available. Remember that a life analysis is typically performed for each equipment block. This establishes the pattern of future failures for each equipment. This pre-work expedites the evaluation of the other risk categories. For example, if a specific equipment failure can cause a safety or environmental event, the corresponding risk calculation is straight forward. And subsequently included in the Criticality Analysis.

Production output values are crucial to generate revenue in an industrial operation. And recorded accurately. Risk categories other than Production are often estimated. And not as precise. Additionally, their risk estimation introduces biased assumptions in the evaluation process. Therefore, the Analytic Hierarchy Process (AHP) is suggested for non-production risk category evaluation.

The Analytic Hierarchy Process method

The Analytic Hierarchy Process (AHP) is a method for handling quantifiable and/or intangible criteria in decision-making processes. It is a multicriteria decision-making approach that is based on the idea of pairwise comparisons of alternatives with respect to a criterion. For example, which alternative, A or B, is preferred and by how much more is it preferred? Or with respect to a goal, which is more important, A or B, and how much more important is it? By employing the pairwise comparison method, the relative importance of one criterion over another is easily assessed. Thus minimizing biased decisions. The loudest person in the room does not win the argument in this case.

In summary, a RAM model can greatly enhance the accuracy of a Criticality Analysis exercise. Insufficient on its own, but combined with a pairwise comparison method, it can cover all risk categories. It is important to note that building a RAM model provides numerous other solutions for the Asset Management Program, extending beyond Criticality Analysis. It is an extremely valuable tool in itself.

Good post.