Your maintenance backlog is a queue of work orders. You can manage maintenance backlogs more effectively by applying queuing theory.

When maintenance work order time estimates are close to actual times, queuing theory can be applied to schedule the most effective arrangement of your maintenance backlog.

If your maintenance backlog work order time estimates in are within 5-10% of actual completion times it is best to arrange your maintenance work orders into queues of scheduled jobs that take similar time to do. Then set up your crews to work through each queue with organised campaigns that start and complete each queue to schedule

Maintenance work order scheduling can be done more scientifically if you use queuing theory. Normally the Maintenance Scheduler looks at the maintenance backlog and allocates work orders to the maintenance crew in order of job priority. They then use the estimated times on the chosen work orders to balance the work load across the maintenance crew so everyone has enough jobs to do on each work day. That approach fills the weekly maintenance work schedule, but that may not be the best way to get through your maintenance backlog.

My bank just put in a queuing solution. You go through the front door and in the entrance foyer is a panel like the one shown in the image below with four buttons. You press the top button if you want to see a bank teller to do your over-the-counter banking transactions. The second button down is for advice about bank accounts, like starting one or closing one. The third button is for major financial queries, like superannuation or a loan, and the fourth is for everything else.

Once you get your printed ticket you go and sit in your allocated queue and wait your turn. But the most interesting part is what happens next.

There are enough bank tellers so that anyone who wants an over-the-counter transaction gets served within two minutes of joining the queue (usually it is much sooner). There are enough service staff that if you have a long financial query of 15 to 30 minutes duration you are seen by one of them within ten minutes (often it so much sooner). The bank schedules its resources to match the times that their typical range of work activities take.

Instead of letting any customer go to any person in the bank, the bank queuing solution first categorises customers into how much time is needed to complete their inquiry. The current size of each queue is used by the bank to allocate its people so that all customers get served in a fair time. Had customers been allowed to go to any bank staff they wished, you would never know how long anyone would take to handle a customer request. One query might take two minutes and the next one might take thirty minutes. You would be unable to allocate your people effectively to match specific customer needs.

Maintenance work orders can be handled the same way. You divide your backlog into definable queuing criteria and allocate your maintenance resources accordingly to get through each queue in good time. The image below shows how the bank’s queuing solution can be used in maintenance backlog work order scheduling.

Once the work is subdivided you put the high priority jobs in each queue to the front of its category. Your manpower, equipment and other job resources and requirements can then be allocated to each queue to match the rate you want to shorten a queue. The maintenance crews work through the scheduled queues of work orders from the top priority job to the least priority job until the queue ends.

By doing your maintenance work order scheduling using queues you will get through your maintenance backlog jobs faster. Your people and resources ‘fine-tune’ the particular type of work they do and learn to do it very efficiently. They do the work faster and they find the simple and easy ways to get through the queue. In fact, once your maintenance crews are specialised in doing their work order queue they no longer need a supervisor. They become autonomous maintenance crews highly skilled and knowledgeable in addressing the maintenance work orders in their backlog maintenance jobs queue.

Maintenance backlog work order management using queuing theory is a very effective technique to slash the length of time that work orders sit in your maintenance backlog. But you need accurate work order time estimates in order to get the best results from this methodology of work order queue management.

Even if your work order time estimates are inaccurate, the concept of maintenance queue management is sound. You can still categorise poorly planned work orders roughly into queue types. The work order queuing categories are your own choice. They need to clearly segregate all your maintenance work orders into queue types that make sense for your operation. You can include your resource constraints into the queue criteria, like the need for specialist access equipment, such as the overhead access device noted in the work order queue category list below.

- Less than two hour using only standard tool kit

- More than two hours and less than four hours using only standard tool kit

- Less than four hours and requiring overhead access equipment

- More than four hours but less than eight hours and requiring overhead access equipment

- Etc, etc

Once you have a queue of work you must stop queue jumping

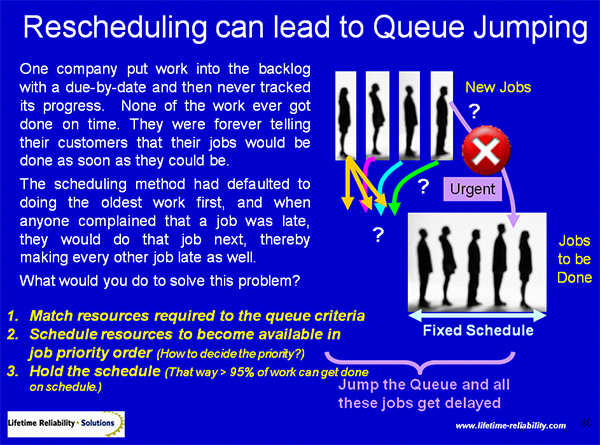

The bank works through each queue of customers in order from the first in the queue to the last in the queue. No queue jumping is allowed. Unfortunately in the world of maintenance new work of high priority can suddenly appear. That can lead to the bad practice of stuffing high priority work in at the front of the queue.

The image below explains how a the machine shop pushed late customer orders to the front of the job queue so that those jobs were next done. But that then made every job late and guaranteed future irate customers would demand that their work be made urgently. Queuing jobs works if the queue is taken in order. When you stuff more work into the available time the queue will grow. A longer queue will take more time to process.

It is vital that the estimated time for your maintenance jobs be right so that you know how much time the resources put onto the queue will take to do the workload. It is why the bank categorises its customers by type of query. The query type tells them the time that it will take to work through each queue and lets them move people to the slow queues when the waiting time gets too long.

When urgent maintenance work arises you need to closely estimate the time to do the job and then take out a less important job of the same duration from the queue and slip the urgent job into its place.

The other option is to make a new queue only for urgent jobs and put people and resources aside to do those unknown, but sure to happen, priority jobs—these are known in the maintenance game as emergency maintenance work orders. They create nightmares for maintenance crews if you put them in front of the scheduled maintenance work. They need to have a separate ’emergency’ queue that does not impact your scheduled workload. If you put emergency work orders first at the queue you are sure to get a poor scheduled planned compliance result that day.

There is a lot of value in seeing maintenance work orders as a queue of work and not just a list of jobs on a maintenance backlog print-out. Within the backlog there is order in the seemingly random array of work. But you first must put the jobs into categories of time duration and resource requirements. That gives you a way to create order from chaos and lets you build queues of work in priority order.

Once you have ordered queues you can easily match men and resources to get through each queue as fast as you want. Applying queuing theory helps you to organise, control and master your maintenance backlog management.

Best regards to you,

Mike Sondalini

Director

Lifetime Reliability Solutions HQ

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply