Every organization and organism’s performance is limited to the capability of its design. If you want better business results, then get or build a new organization with systems designed to naturally deliver the outcomes and profits you want. Nothing else you do will ever work as well!

Keywords: business system design, business process management

One definition of a system noted in the online Merriam-Wester dictionary is: a regularly interacting or interdependent group of items forming a unified whole. You are a system. You live within numerous human, familial and natural systems. The organization you work in is a system. It belongs to many business, community and commercial systems. All systems span across space and time. What is done in a system today affects what happens tomorrow in many places.

Once a system is created its maximum performance is dictated by its design. It performs as well as is permitted by the combined effects of those “interacting or interdependent group of items forming a unified whole.” A school is a system, as is a university, as is a home, and the peoples each one creates are a system result. A starfish crawls, and even though it has arms it cannot climb trees. It lives a life matched to and constrained by its physical and environmental systems’ designs.

The systems you live in give you the life you get. I’d love to be an Olympian high jumper and many times I have fanaticized a gold medal. But my body, my own physical system, design will never allow that to happen because my muscular and skeletal structure is incapable of such feats. It would have been a pointless waste of years of my life trying to jump to world record heights.

Every system is limited by its design. A system cannot be better than what it can be, nor can it do more than what its design permits. The fact that everything is a system, that each system plays a part in many systems, and that the performance you get from any system is a design outcome is important to grasp if you are to have a better personal or corporate future. If you have a stable system you will only get whatever the system will deliver. There is no point setting goals or measuring performance because the system already gives you what it can deliver.

The results a system gets are expressions of its natural, inherent behaviours. You can only get out of a system what its parts have the combined capacity to achieve. It explains why starfish live underwater—it’s what its design requires—and why organizations are hardly ever as successful as their owners and managers want them to be—they cannot be a great company because their component parts aren’t built to deliver great performance.

It’s sad news that I have for you about your current organization—if it’s not already a world class performer it is never going to change into a world class performer.

A company survives, it makes money, it meets budget. That is all any business manager wants to achieve. To do more than what the company is now doing will require its management and its culture to change away from the internalized paradigms and inbuilt practices that combine together to deliver the current range of performances and their subsequent results. Employees will never be able to change their organization. Those changes are the duty of the company owners and upper management to do. But there is one thing middle managers and supervisors can try that I’ll explain later.

Your organisation is a stable system. You cannot change stable systems. As much as you may hate what you see happening in the organization, it survives well enough and remains in business. Even though it could be a wonderfully better and more successful company there is no internal drive at the most senior management levels to be such a company. It’s not worth losing a minute of sleep over a company’s performance or what it could become… if only it would change. Don’t waste your time fixing an existing company. Either accept things as they are, or get out and get a job that you love to do, or start a new company designed as you want it to perform.

Stable systems do not change. When their world or environment changes around them a stable system adapts as much as it can, after which it dies out. Your company lives today as its particular system design permits, and if nothing significant changes in its business environment it will also be here tomorrow doing exactly what it does now.

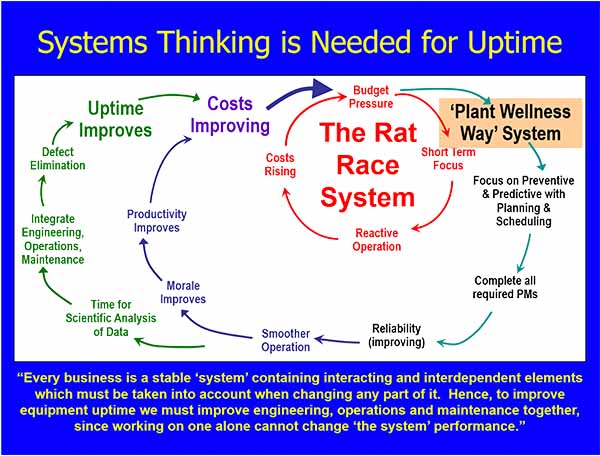

The only option you have is to start a new system that is designed, built and resourced to achieve and live in the better future you want to be in. You need to do what is shown in Figure 1. You have to start a totally separate and independent system that is not poisoned by the beliefs and values of out of date management mind-sets and stifling organizational culture.

If you want to do something great within an existing organization start your own team using volunteers. Keep the team separate to the rest of the organization. Build your own self-contained system of right thinking people doing the right practices. If the new system performs better than what the company can now do, it will either be killed off by the organization to protect itself from change, or the new system will eventually replace the organization in its image.

It is impossible to make successful change in the current organization until all senior managers willingly want the new future. Owners and top management must act to replace the old system with a new system that can deliver a better organization, and they must be seen to approve the redesign by providing the resources and finance needed to change to a different, better performing, and stable system.

Because an organization is a system living within systems, and each system causes influencing behaviours in the other systems across both time and space, a great number of things about a company and the systems outside of the company may need to change in order to achieve and sustain a more successful future. Where major enhancements and reengineering needs to be done in an organization it may be better to dismantle the current configuration and build a totally new business system design.

Many companies want to change for the better and many of them undertake internal change programs. They redesign their processes, issue new procedures and do training of personnel. But the changes will always fail to bring lasting improvement until all systems, both within and without the organization, are changed to a design where their natural outcomes create and sustain the intended improvements. For an organization “all systems” includes each person within the company, each stakeholder impacting the company, and every supply chain vendor outside of the company. It may be necessary to improve or change all those systems in order to get what your organization wants to achieve.

When you must change your company for the better, then take a deep look at using the Plant Wellness Way methodology to design and build your new enterprise. The Plant Wellness Way EAM methodology contains “tools” used to create and reengineer an organization into a more successful system design built to get great performance that is sustained into the future.

All the very best to you,

Mike Sondalini

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply