Use Equipment Criticality to Match Planned Maintenance Strategy to the Operational Risks

Planned maintenance has the purpose of rejuvenating equipment before parts start failing. Use maintenance strategy based on continual renewal to reduce operating equipment risk of failure so that you have your plant and equipment in good condition and thus free of age and stress related defects waiting for the chance to fail.

Abstract:

Match Your Planned Maintenance Strategy to Equipment Criticality. This article takes you through the factors which you need to consider and perform when developing a planned maintenance strategy incorporating both proactive preventive and predictive maintenance. If you are spending the majority of your maintenance effort in reactive tasks then your maintenance costs are high. If you can spend the majority of your maintenance effort doing planned maintenance activities you will lower your maintenance costs and have more reliable production plant.

The approach relies on identifying equipment criticality based on the impact that equipment failure has on production. The failure modes that cause breakdowns are identified and the necessary planned maintenance to address the failures are specified. The required frequency to perform the planned maintenance activity is set so that it is done before a failure occurs.

Keyword: planned maintenance, reactive maintenance, proactive maintenance, equipment criticality,

Objective:

a. To reduce the maintenance costs in the plant to industry standard percentage of replacement asset value.

b. To reduce breakdown maintenance costs below 10% of total maintenance cost for the plant by conducting planned maintenance activities that renew plant and equipment before failure occurs.

Methodology:

The method to achieve the above objectives are summarised in the following steps;

- It is first necessary to check what proportion of maintenance effort is being used on reactive work fixing things verses pro-active work that stops them from breaking in the first place. You want to be spending most of the maintenance time doing proactive work. It is also necessary to identify what proportion of maintenance effort is being used on not doing maintenance related work.Review the last two years history of maintenance work and separate into four categories of Proactive, Reactive, Improvement and Assistance work. Compile costs and man-hours per category to determine proportions of cost and effort spent for each.Proactive includes preventative maintenance, predictive maintenance, condition monitoring, statutory maintenance, etc. Reactive includes breakdown maintenance, corrective maintenance, emergency maintenance, safety or incident related maintenance, etc. Improvement includes equipment or process modifications. Assistance is maintenance resources used in capital projects, plant upgrades, production requirements, etc.

- Collate full plant equipment list from plant drawings, process drawings and equipment asset lists. Be sure to capture all equipment in operation as it will later be necessary to go to component and sub-sub-component levels of analysis, and maybe further.

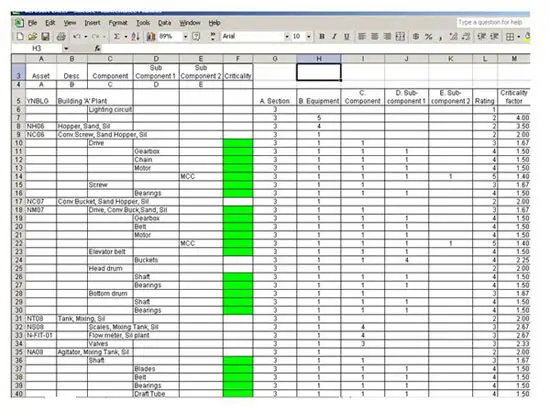

- Using the equipment listing create a spreadsheet showing all the equipment used in each part of the production process. Logically divide the production process into definable sections of the process. Under each section list each item of equipment in process use order.Layout the spreadsheet so that in column 1 you list the process section, column 2 the equipment it contains, column 3 the individual equipment’s components, column 4 the sub-components, column 5 the sub-sub-components.

- It is necessary to identify the impact of losing each item of equipment on production. This is done by conducting a criticality assessment of the plant and the equipment used in each part of the production process.Start by meeting with experienced Operations people to determine the failure impact on production for each item of equipment. Rate the impact of the individual equipment on the process sections using a 5-point scale. 1 is immediate and total impact. 2 is delayed total impact. 3 is reduced or hindered operation. 4 is inconvenience to operation. 5 is no impact.Work your way through all the plant deciding how the equipment impacts on the process should it fail.

- On the same spreadsheet used in the Operations criticality review extend it to include all the equipment assemblies and sub-components under the respective equipment. List down to the lowest sub-assembly or component in the equipment for which you are willing to store as a spare part.Meet with experienced maintenance personnel and rate the criticality of assemblies and components in each item of equipment using the same criteria as previous. For each item of equipment record the spare parts considered critical to have to keep the equipment operating.To get a numerical criticalty rating see the spreadsheet below. Basically you sum the ratings and divide by the number of time an item is rated. If the rating is between 1 and 1.33 it is highly critical and you should consider stocking critical spares. It will require condition monitoring and preventative maintenance. If between 1.34 and 1.67 it is moderately important and a preventative maintenance strategy is required. If above 1.67 it is of lesser importance and a mix of preventative and breakdown maintenance would be considered.

- From CMMS records for past five years identify the failure modes, frequency of failures and the annual maintenance costs per equipment. If the plant has been substantially changed in that time then take the records as from the date of the up-grade commissioning. Where job costs are reliable and accurate, identified costs, man-hour and materials required for regularly recurring repairs to assist future estimating purposes.

- Using Pareto analysis, identify the high maintenance cost equipment recorded in the CMMS during the past five years. Each of the top 20% of equipment items is to later be analysed to identify causes and possible solutions as a separate part to this exercise.

- Conduct an on-site tour and review of plant and equipment with experienced Operations and Maintenance personnel to identify operating problems not reflected in the maintenance records. Identify problem equipment, failure frequency, consequences and spares required for each plant asset. Cross-check the CMMS review outcomes against site tour review results to confirm all issues are recorded.

- Using the criticality spreadsheet, sit down with experienced operators and maintainers and create planned maintenance activities to address high risk and frequent occurrences. Create planned maintenance activities to perform preventative maintenance, condition monitoring, renewal or refurbishment of equipment and components. Set the timing for the planned maintenance so that the activity prevents the failure.Secondly, with the help of operations personnel develop operator inspection and check sheets so that operators can perform watch-keeping activities during their normal rounds.Third, review if the current planned and preventative maintenance activities are still relevant or need to change to suit the new planned maintenance requirements.Fourthly, include activities relating to statutory compliance and other works that will not be identified during this process.

- Develop each planned maintenance activity to have a scope of works with itemised tasks, materials list and cost estimation, provide materials lead time indication, trade man-hours estimation, and the total work order cost estimate.

- For each item of production equipment, cost model the new planned maintenance activities and compare the cost to the current maintenance costs to ensure justification to proceed with changing the maintenance strategy. Review new balance of costs between expected Reactive and Proactive categories to confirm the majority of time is spent on proactive pursuits.

- Catalogue and cost the spares identified as critical requirements for plant and equipment from the criticality analysis.Detail the spares required for planned maintenance activities each financial year for inclusion in the annual financial budget.Update critical spares list and order spares in a controlled and responsible financial manner.

- Prepare the maintenance schedule and budget for the year in advance, including formulating a plan for maintenance on the plant which incorporates the new planned work orders. Update CMMS with the new planned maintenance work order details. Develop the resulting maintenance resource demand into an overall resource schedule.

- Submit the plant maintenance budget into the corporate accounts and track performance.

My best regards to you,

Mike Sondalini

Managing Director

Lifetime Reliability Solutions HQ

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply