What Every Manager Needs to Know About Business Risk from Equipment Reliability

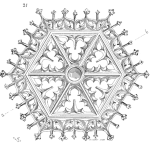

Figure 1 shows how equipment risks start and transfer through a business. Tens of thousands of business risks, even hundreds of thousands in big operations, come from your plant and machinery.

A Physics of Failure (POF) mechanism is any of the little more than a dozen ways by which the atomic structure or microstructure of equipment parts can fail. POF mechanisms include: chemical attack of the atomic structure; abrasion and erosion; overloaded microstructures from compression, shearing, bending or twisting; cyclic fatigue; poor manufacture of the microstructure; bad machining methods. The events that put POF mechanisms into your plant and equipment happen throughout the asset and business life cycles.

Once failure mechanisms are inside or on your machinery they relentlessly attack the parts, trying to destroy their physical structure. One POF mechanism brings many consequential risks to components, which immediately transfer as risks to your operation. All failure mechanisms migrate risks up the asset hierarchy and wait to be the root cause of production problems and losses. As Figure 2 shows, plant and equipment is failed by us—machinery doesn’t harm itself.

Unless prevented, each item of equipment in an industrial operation, such as electric motors, automated valves, pump wet ends, etc., can give you in the order of 10 to 100 risks from the range of POF mechanisms present within their parts. For operations with hundreds of machinery and equipment items the business can continuously be carrying tens-of-thousands of operating risks. For sites using tens-of-thousands of equipment items there could be hundreds-of-thousands of risks sitting in the operation ready to cause new production problems.

The situation of tens-of-thousands to hundreds-of-thousands of endless risk creation opportunities from failure mechanisms continues forever in a company until you intentionally act to get rid of their causes. The only place you can stop all POF induced operating equipment risks is at the very bottom of the physical asset risk hierarchy. If you only work at the component level and above, you leave behind thousands and thousands of causes that will start new problems.

When it’s important for your company to have world class equipment reliability, then it’s vital that owners, executives and managers know there is only one way to get such reliability: eliminate all parts’ microstructure failure mechanisms, and prevent their return. Top management might be advised by specialist maintenance and reliability consultants, and even their own people, to try a range of risk elimination and reliability improvement strategies. Ultimately they will be unsuccessful if the strategies used leave tens-of-thousands of never-ending failure risks inside and on your machinery and equipment.

POF mechanisms unceasingly try to destroy the microstructure health of your equipment parts. They create thousands and thousands of risks in your business. These multitude of risks provide opportunities to combine in unimaginable ways to constantly produce production troubles and maintenance problems. Some of which will become big disasters.

If in the past you’ve tried to get high reliability equipment, but today you still have equipment maintenance and reliability problems, then contact your nearest Plant Wellness Way Consultant online at https://plant-wellness-way.com/about/regional-contact-list/—they know exactly what to do to eliminate the deepest causes of your operation’s current and future equipment failures and plant downtime.

All the very best to you,

Mike Sondalini

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply