Monte Carlo analysis, or Monte Carlo simulation, is a technique for forecasting that accounts for uncertainty and variability. As an analytical tool, Monte Carlo analysis forces the project development process to incorporate wider thinking and minimize biases. As a communication tool, Monte Carlo analysis is powerful in showing the probabilities and possibilities and identifying the input parameters that impact a specific project context.

Monte Carlo analysis is now more convenient and affordable than at any point in its 70-year history. The technique provides huge additive value for large and complex projects and capital-intensive programs.

Caveats

Out of the gate, let me say that I love Monte Carlo analysis. I have used the approach for over thirty years. I have degrees in engineering and finance. I built an asset management practice that used MCA as a core technique and even did a keynote address at an international user conference on how to do it.

Some of those reasons include that Monte Carlo analysis is often poorly communicated and the technique misses the rare events that are the source of catastrophic project results.

Reliability Engineers Thinking In Ranges

According to Gustavo Vinueza, you may be in the ballpark with high, medium, and low estimates of input parameters. However, forecasts based on a single-point estimate for each parameter are science fiction. Simply, Monte Carlo analysis allows you to explore uncertainty. It forces you to start thinking in ranges.

What is Monte Carlo Analysis

Monte Carlo Analysis is a computer-based method of analysis developed in the 1940s that uses statistical sampling techniques to obtain a probabilistic approximation to the solution of a mathematical equation or model. This 1997 definition from the United States Environmental Protection Agency is painfully simple, but a few key insights can be gained from it.

Uncertainty and Variability

Monte Carlo simulation uses thousands or millions of permutations of random variables to calculate all possible outcomes. The probability distribution it generates makes it an effective tool in forecasting uncertainties and variability experienced in many project management applications.

There is a fine difference between uncertainty and variability. Uncertainty is quantified by a probability distribution related to the likelihood of an uncertain quantity’s single, true value. Variability is quantified by a distribution of frequencies derived from observed data of multiple instances of the quantity.

Strengths According to ISO 31010

ISO 31010 is the supporting standard for the international risk standard (ISO 31000) and provides guidance on the selection and application of systematic techniques for risk assessment. Five of Monte Carlo analysis strengths include the following:

- the method can accommodate any distribution in an input variable, including empirical distributions derived from observations of related systems

- models are relatively simple to develop and can be extended as the need arises

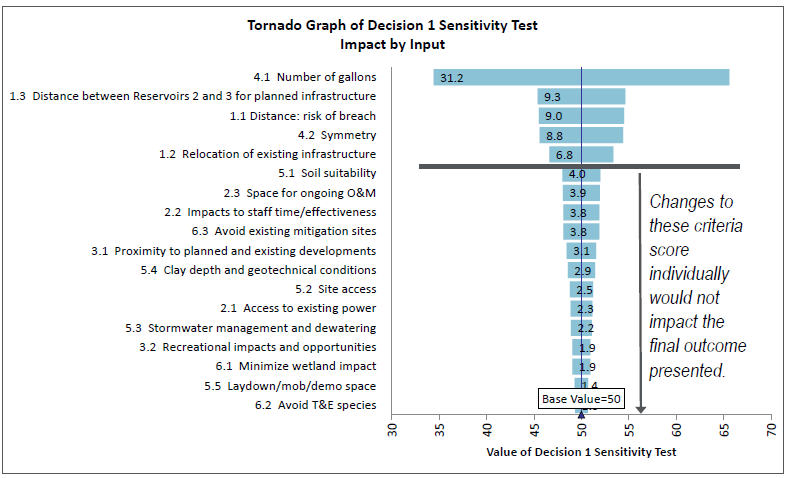

- sensitivity analysis can be applied to identify strong and weak influences

- models can be easily understood as the relationship between inputs and outputs is transparent

- software is readily available and relatively inexpensive

Questions to Ask Before Performing a Monte Carlo Analysis

Questions to consider at the initiation of a quantitative variability and uncertainty analysis, such as Monte Carlo analysis, include:

- Will the quantitative analysis of uncertainty and variability improve the assessment?

- What are the major sources of variability and uncertainty? How will variability and uncertainty be kept separate in the analysis?

- Are there time and resources to complete the analysis?

- Does the project warrant this level of effort?

- Will a quantitative estimate of uncertainty improve the decision? (How could the decision change?)

- What types of skills and experience are needed to perform the analysis?

- Have the weaknesses and strengths of the methods been evaluated?

- How will the variability and uncertainty analysis be communicated to the public and decision makers?

The Greatest Value: Insights

The most important aspect of a quantitative variability and uncertainty analysis is the interaction between the analysts, decision makers, and other interested parties, which makes risk assessment a dynamic rather than a static process.

Uncertainty Requires Effective Communication

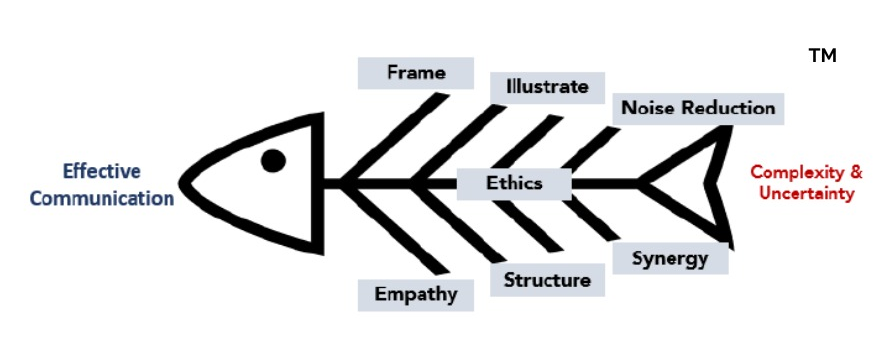

One of the most important challenges is effectively communicating the sources of variability and uncertainty and their impacts. Higher levels of complexity and uncertainty typically make Monte Carlo analysis more attractive, as it facilitates communication.

Ironically, insights gained from a quantitative analysis are generally qualitative in their expression and understanding. Insights can include an understanding of the following:

- the degree of variability and uncertainty and the confidence that can be placed in the analysis and its findings related to the project budget, schedule, and quality.

- the key sources of project delivery variability and uncertainty and their range of impacts

- the critical assumptions and their importance to project agreements and risk management

- the unimportant assumptions and why they are unimportant

- the extent to which plausible alternative assumptions or risk and uncertainty mitigation could affect the project

- the key project development controversies and a sense of what difference they might make individually and collectively

Implementing Monte Carlo Analysis with FINESSE

Monte Carlo analysis or Monte Carlo simulation is a technique used for forecasting that considers uncertainty and variability. As an analytical tool, Monte Carlo analysis forces the project development process to incorporate wider thinking and minimize biases. As a communication tool, Monte Carlo analysis is powerful in showing the probabilities and possibilities and identifying the input parameters that impact a specific project context.

Monte Carlo analysis is now more convenient and affordable than at any point in its 70-year history. The technique provides significant added value for large, complex projects and capital-intensive programs. For routine projects with low complexity and uncertainty, an incremental approach, in which Monte Carlo analysis is conducted after traditional high-, medium-, and low-level analyses, is most practical.

FINESSE provides a proven cause-and-effect approach to effective communication in high-complexity, high-uncertainty contexts. Communicating the results of Monte Carlo analysis is well-suited to the FINESSE approach.

See also: Solomon, J. D. (2023, March 15). Why embrace Monte Carlo analysis for new project development. JD Solomon Solutions. https://www.jdsolomonsolutions.com/post/why-embrace-monte-carlo-analysis-for-new-project-development

The elements of the FINESSE fishbone diagram® are Frame, Illustrate, Noise reduction, Empathy, Structure, Synergy, and Ethics.

Need help getting started? JD Solomon Inc. provides practical solutions for Monte Carlo Analysis for reliability programs.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply