Failure Fingerprint: Plastic Deformation in Bearings

(Also known as “Brinelling,” “False Brinelling,” or “Plastic Flow” depending on cause and appearance)

Abstract: Unlike fatigue cracks or abrasive wear, plastic deformation represents a threshold failure where the material’s yield strength is exceeded, leading to permanent dimensional change. In high-precision components like bearings, even microscopic plastic flow the “failure fingerprint” can trigger catastrophic system vibration or total seizure. This article explores identifying markers of Brinelling, torsional yielding, and metallurgical slip.

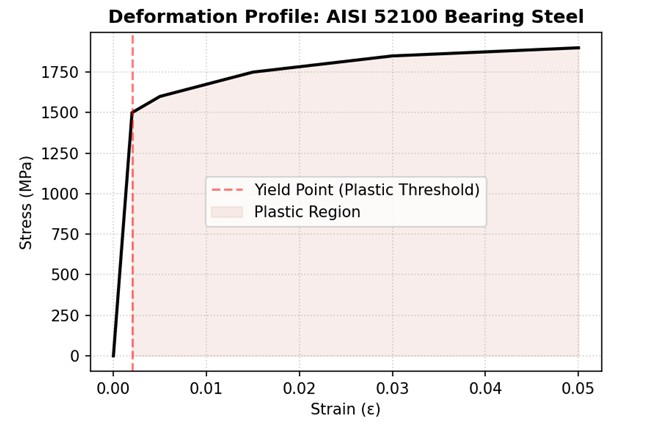

Plastic Deformation: Mechanism of Failure

Plastic deformation occurs when mechanical stress exceeds the elastic limit of the alloy. For standard AISI 52100 bearing steel, this yield point typically hovers around 1,500–1,800 MPa. Once reached, dislocations within the crystalline lattice move permanently along slip planes. In bearings, this is often localized (hertzian contact stress), while in shafts, it is frequently a bulk phenomenon (torque overloads).

Bearing Failure Fingerprint

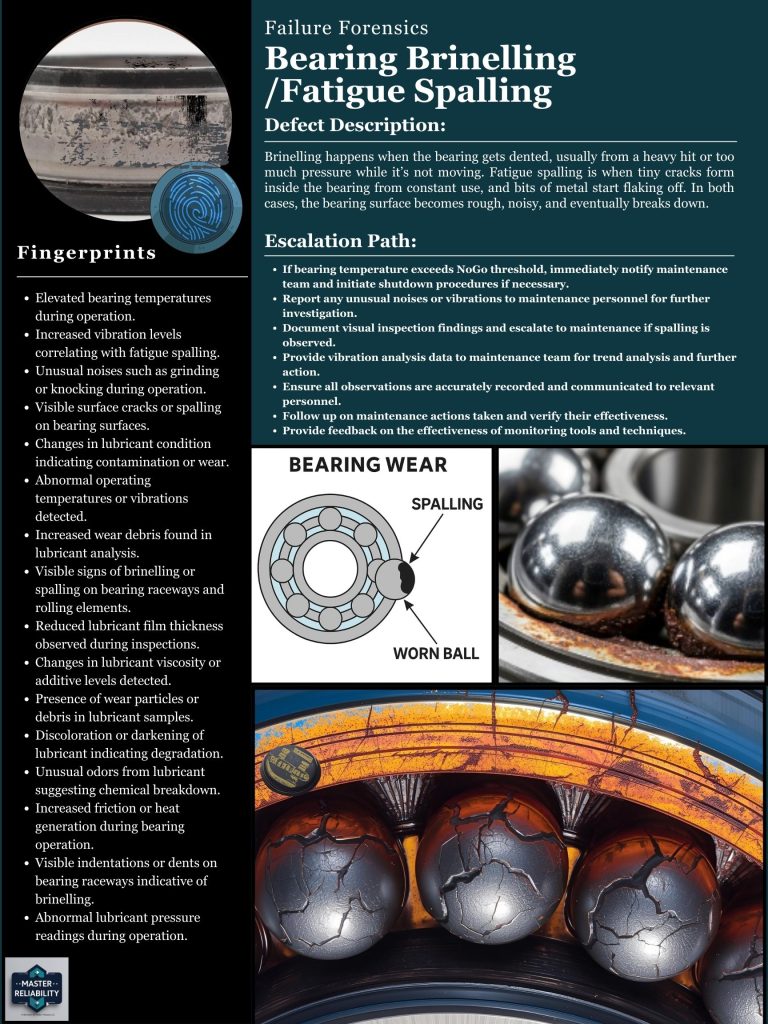

True Brinelling

True Brinelling is characterized by permanent indentations in the raceways. The fingerprint is distinct: the indentations often retain the original grinding marks of the manufacturing process at the bottom of the crater. This indicates the material was pushed aside by static overload (e.g., a heavy impact or improper mounting) rather than worn away by friction.

Fingerprints:

- Elevated bearing temperatures

- Increased vibration

- Unusual noises

- Visible surface indentation, cracking, pits

- Lubrication contamination from particulates

- Change in lubrication viscosity

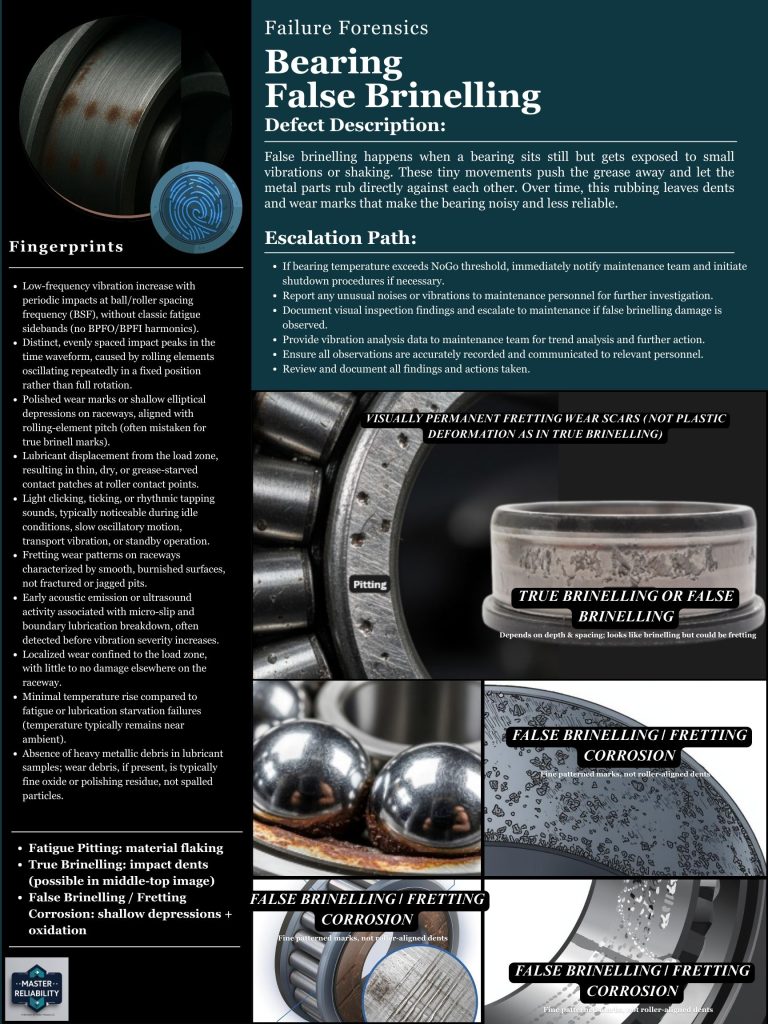

Key Diagnostic: If the indentation shows a “lip” or raised edge of displaced metal, it is confirmed plastic flow. If the metal is smooth or polished, it is likely “False Brinelling” caused by vibration.

False Brinelling

False Brinelling is often confused with plastic deformation, this is actually a wear phenomenon. However, long-term false brinelling can lead to “fretting,” which eventually weakens the surface and lowers the threshold for actual plastic yielding under lower loads.

Fingerprints

- Polished wear marks or shallow elliptical depressions on raceways

- Lubricant displacement from the load zone

- Light clicking, ticking, or rhythmic tapping sounds

- Fretting wear patterns on raceways

True brinelling is characterized by permanent impact indentations caused by plastic deformation of the bearing surfaces. This damage produces wear particles that are carried away by the lubricant, contributing to lubricant contamination. In contrast, false brinelling occurs when vibration or small oscillatory motion displaces lubricant from the raceway contact zone, leading to localized lubricant starvation rather than material displacement from heavy loading. Put simply, excessive or improper loading tends to create surface damage that sheds debris into the lubricant, while vibration without adequate rotation primarily leads to lubricant loss at the contact points.

Fingerprints of Bearing Plastic Deformation

Above is an AI image illustrating Plastic Deformation.

| Category | Description |

|---|---|

| Surface Appearance | Localized dents or depressions in raceways and/or rolling elements; evenly spaced around the circumference corresponding to rolling element pitch. In severe cases, flattened spots or smeared surfaces. |

| Texture | Polished or mirror-like in advanced cases; sometimes with raised edges or microcracks at dent boundaries. |

| Location | Typically, on load zone of stationary race; in false brinelling, marks may occur 180° apart, matching vibration frequency. |

| Lubrication Clues | Discolored or contaminated grease from metallic wear debris; metallic “sparkle” under light. |

| Progression | Initially cosmetic, but the dents cause high stress concentrations leading to early spalling or fatigue pitting. |

Failure Progression

End-of-life may be predicted for a bearing experiencing plastic deformation by matching the current state of the bearing to the failure stage. Operators may be trained to look for these fingerprints during their normal inspections and report out when a deviation has occurred. In TPM, operator’s fill out a defect card when a defect is detected.

| Stage | Description |

|---|---|

| 0 – Stable | No visible defects; normal contact stress. |

| 1 – Yield Initiation | Local stress exceeds yield strength; micro-indentations begin. |

| 2 – Surface Flow | Dents form under stationary rolling elements; surface microcracks appear. |

| 3 – Plastic Flow Expansion | Dents deepen, raised edges increase stress; lubricant contamination begins. |

| 4 – Secondary Fatigue | Microcracks propagate from dents → pitting/spalling. |

| 5 – Functional Failure | Bearing roughness severe; high temperature, noise, and vibration. |

Note: Typically, Operators are able to begin detecting any deviation from the norm in stages 3 and 4 of failure progression lifecycle.

5-Sense Diagnostics

| Sense | Observable Fingerprint |

|---|---|

| Sight 👁️ | Dents on raceways, mirror-like spots, debris sparkle in grease. |

| Sound 👂 | Rhythmic ticking or rumbling under load. |

| Touch ✋ | Resistance when hand-rotating the bearing; “notchy” feel. |

| Smell 👃 | Burnt or metallic odor if lubricant overheats. |

| Temperature 🌡️ | Localized heat at the raceway zone under deformation. |

Root Causes of Bearing Plastic Deformation

- Excessive static or dynamic load beyond yield strength of the bearing material.

- Shock loading during installation or operation.

- Vibration under static load without rotation (false brinelling).

- Improper mounting (hammer blows, press misalignment).

- Inadequate internal clearance or tight fits causing over-stress.

Prevention & Detection

Detecting plastic deformation before a breach occurs requires precision monitoring. Vibration Analysis in bearings can catch the rhythmic pulse of a brinell mark long before the bearing “feels” rough to a manual check. In shafts, Laser Alignment and run-out sensors are the primary tools for identifying permanent bends. To prevent these signatures, design safety factors must account for “Shock Loads.” A bearing rated for 10kN service can fail instantaneously if a 30kN surge occurs for even 5ms, as the hertzian contact area is tiny, causing local pressure to skyrocket past the yield limit.

Conclusion

Plastic deformation is a permanent record of an event that exceeded the component’s design limits. By examining the topography of indentations in bearings forensic engineers can reconstruct the magnitude and direction of the failure-inducing force. Distinguishing between wear (material loss) and plastic flow (material displacement) is the fundamental step in any root cause analysis.

Once the root cause is identified, corrective and preventative measures may be put in place to eliminate future occurrences of bearing plastic deformation.

Further Reading:

ISO 15243: Rolling bearings — Damage and failures.

ASM Handbook, Vol 11: Failure Analysis and Prevention.

Join us on our YouTube channel for the free lecture: Thermal Expansion & Shaft Failure — Explained! 🔥 LS-005

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply