DYNAMICS OF HEAT IN COMMERCIAL PIZZA OVEN MECHANISMS

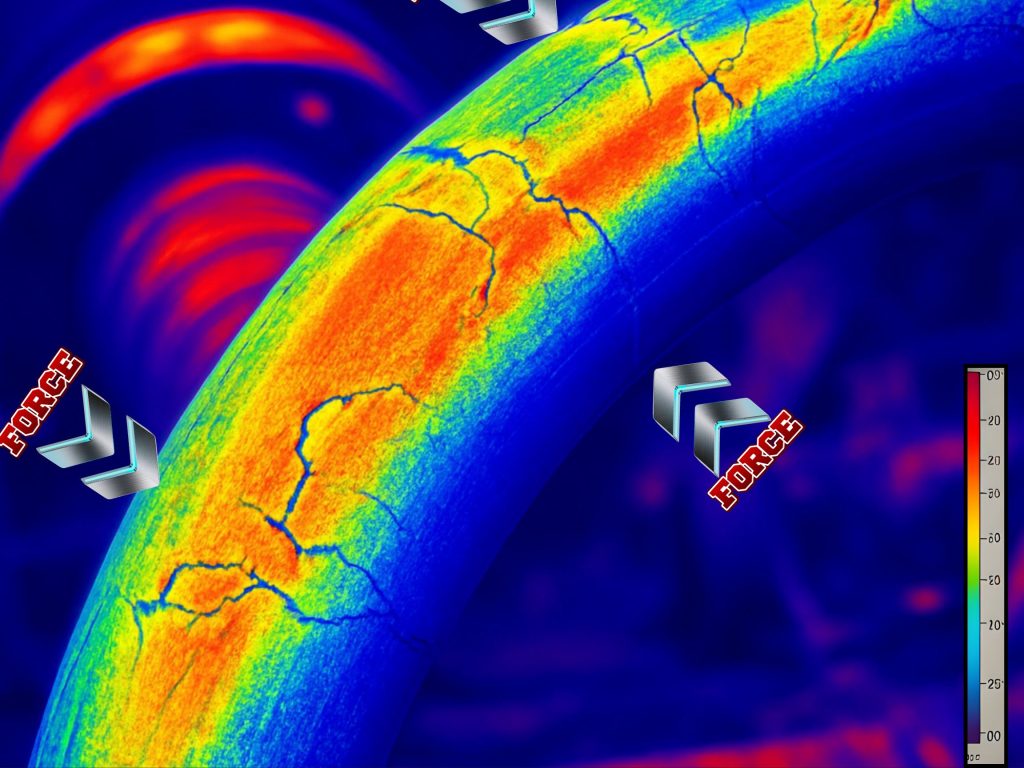

Thermal stress on shafts leads to premature failure. Understanding the factors that influence the bending forces of shafts and implementing counter measures can significantly increase their longevity.

Commercial pizza ovens are engineering marvels designed for a singular, high-intensity purpose: the rapid and consistent delivery of heat to dough and toppings. Operating at temperatures frequently exceeding 800 degrees Fahrenheit, these systems rely on a complex interplay of radiation, convection, and conduction. While the culinary focus is on the crust, the mechanical burden falls squarely on the internal components, most notably the heavy-duty shafts that drive conveyor systems and rotating decks. These components serve as the backbone of the operation, inside large, industrial-sized ovens where they undergo extensive temperature gradients.

In this article, we will observe the factors that influence bending forces and their countermeasures.

The Mechanical Environment of the High-Heat Hearth

During normal operation, a pizza oven is a landscape of extreme gradients. The internal environment is rarely static; it is subject to frequent and rapid temperature fluctuations. Factors that influence bending forces: the initial morning startup, the nightly shutdown, the periodic opening of doors for inspection, and the constant loading and unloading of cold products. Each pizza introduced into the oven acts as a localized heat sink, drawing energy from its immediate surroundings and creates “thermal valleys” in an otherwise searing environment.

Furthermore, airflow behavior inside the oven leads to uneven heat distribution. Modern impingement ovens, for instance, use high-velocity air jets to strip away the “boundary layer” of cool air around the food. However, this same airflow creates “hot spots” and “cold spots” across the mechanical assembly. For a drive shaft extending through the oven wall, this means the portion inside the chamber may be at 800°F while the portion outside, linked to motors and bearings, is closer to ambient room temperature. This extreme delta-T is the primary driver of longitudinal thermal stress and can lead to binding if tolerances are too tight.

“Uneven heat distribution, driven by turbulent airflow, generates internal shear forces within the shaft assembly.”

Understanding Thermal Expansion and Stress Mechanics

Shaft Bowing and Thermal Cracking

Thermal stress in metals is primarily an issue of constrained expansion. As the temperature of a steel shaft rises, the kinetic energy of its atoms increases, leading to a physical expansion in length and diameter. The Coefficient of Thermal Expansion (CTE) determines the magnitude of this change. In a perfectly uniform heating environment, a shaft would expand freely. However, pizza ovens provide anything but uniformity. When a shaft experiences a temperature gradient where one side is hotter than the other due to airflow or proximity to a heating element it attempts to expand unevenly. Because the shaft is a single rigid body, the hotter section pushes against the cooler section. This internal conflict generates significant thermal stress.

In extreme cases, these stresses can exceed the yield strength of the material, leading to permanent deformation (warping) or the initiation of micro-cracks that propagate over time. The geometry of the shaft, typically a long, slender cylinder, makes it particularly susceptible to “bowing” under these uneven loads.

Cause

Thermal Stress develops when components experience rapid, non-uniform heating and cooling. Hot zones expand while cooler zones lag behind, creating thermal gradients within the same component. Airflow dynamics inside the oven strongly influence thermal gradients. The size and shape of a metal component is permanently modified when metal components are heated beyond their elastic limit.

Key contributors include:

- Turbulent airflow patterns creating localized hot and cold spots, and thermal gradients

- Dead zones with limited circulation allowing heat to stagnate or dissipate unevenly.

- Fan performance degradation (wear, imbalance, fouling) altering designed airflow paths

- Damper position, leakage, or control drift causing uneven heat distribution

- Rapid heat-up and cool-down cycles during production changes

- Material CTE mismatch relative to operating temperature range

- Mechanical constraints preventing free thermal expansion

- Exposure to cleaning chemicals, moisture, or food residues that promote corrosion during thermal cycling

Technical Note: Thermal fatigue is a cumulative process. Each startup and shutdown cycle represents a “thermal excursion” that consumes a portion of the component’s fatigue life, potentially leading to catastrophic failure even if the peak temperatures remain within the material’s theoretical limits.

Negative Synergism: Internal Components and Material Fatigue

While the shaft is the primary focus, it does not operate in isolation. It is the structural nexus for metal conveyor belts, pizza pans, and support frames. These components often consist of different alloys with varying CTEs. As the oven heats up, a stainless-steel conveyor belt may expand at a different rate than the carbon steel shaft it wraps around, leading to changes in tension and tracking issues. Shafts are particularly vulnerable because they are the point where mechanical torque meets maximum thermal load.

A warped shaft creates a “camming” effect, where every rotation introduces a structural vibration into the system. This vibration accelerates the wear on high-temperature bearings and can lead to the binding of the conveyor belt. The repeated cycle of thermal expansion and contraction also works against any fasteners or pressed-fit components, causing them to loosen over time through “thermal ratcheting,” where parts expand but do not return to their original seated position upon cooling.

Impact

Over repeated thermal cycles, these combined thermal and flow-induced stress accumulate and can lead to:

- Thermal bowing and warpage of shafts, conveyor frames, belts, and pans

- Permanent deformation affecting alignment, belt tracking, and clearances

- Thermal cracking initiating at high-gradient regions and stress concentrators

- Stress corrosion cracking (SCC) where thermal stress overlaps with corrosive exposure

- Reduced component life, increased maintenance, and degraded bake uniformity

Mitigation Strategies and Design Considerations

Designing for pizza oven shafts requires a balance of material science and mechanical cleverness. High-nickel alloys and specific stainless-steel grades (such as 309 or 310) are often preferred for their high-temperature strength and oxidation resistance. From a design perspective, “floating” supports are often used. These allow the shaft to expand axially without being constrained by fixed bearings on both ends. Furthermore, sophisticated control systems can help manage thermal stress by implementing controlled ramp-up and cool-down cycles, preventing the “thermal shock” that occurs when an oven is blasted to full power from a cold state.

Conclusion

In conclusion, the thermal stress on shafts in commercial pizza ovens is a byproduct of the very heat that makes the product possible. Longevity in these systems is not achieved by resisting the heat, but by accommodating the inevitable movement and stress that heat creates. Through careful material selection and design that allows for thermal “breathing,” manufacturers ensure that the oven remains as reliable as it is efficient.

This article is the first in a multi-part series on thermal stress–related shaft failures.

The articles that follow will focus on identifying thermally induced shaft damage, the inspection methods that reveal early warning signs, and the targeted maintenance actions that can interrupt the failure progression before it escalates into permanent deformation or fracture.

Tagline: Thermal failures don’t start with cracks, they start with airflow, constraints, and maintenance blind spots.

Join us on our YouTube channel for the free lecture: Thermal Expansion & Shaft Failure — Explained! 🔥 LS-005

Spot Component Issues Using Thermal Imaging – Accendo Reliability

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply