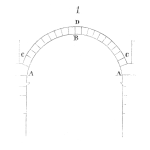

In this final article of the series, we will cover the right leg of the “V” diagram which illustrates the process of verifying and integrating hardware into the system.

The goal of systems/validation engineering, once hardware and software is available, is efficiently integrating, verifying and performing final validation of the product.

Here we are ensuring all components, subassemblies and subsystems work together as required; full functionality of the system is successfully verified, meets validated requirements and customer needs are met. Some notable considerations are as follows:

Subsystem and System Integration

Of course, components, subassemblies and subsystems are assembled into the system and tested together. This is often a priority in the development process to ensure confidence in the functionality of integrated hardware. (Also, early integrated prototypes are often used for firmware and software development.)

This may or may not occur prior to ‘stand-alone’ bench testing…usually some amount of bench testing (such as basic power-up) is performed before testing on other initial prototypes.

Design Verification & Product and Process Qualification

As highlighted in Part 3 (assuming fully developed test equipment is available) each subassembly can be verified in “stand-alone” bench testing prior to or in parallel with integration testing. This activity contributes to product and process qualification, in particular, if multiple samples of subassemblies are available to measure variability/yields in manufacturing (process capability). Of course, successful integration contributes to product (system) verification, and multiple integrated systems with high yields contribute to system-level product and process qualification.

Final Verification and Validation

As described in the article “What is Validation?”, recall that validation is the completeness and correctness of requirements. Final verification and validation therefore defines the following:

Final product – implies the final system hardware/design or end-product provided to the customer. Final also implies the last step in the development process prior to delivery to the customer.

Final Verification – recall we are verifying against valid requirements to the maximum extent possible.

Final Validation – where a requirement isn’t entirely correct or complete, validation can be accomplished through testing in the customer’s environment. This testing is an opportunity to define the requirement (and associated conditions) further, in addition to establishing acceptability of the product by the customer. Also, even with a valid requirement, an “in-house” test condition may not fully represent the customers intended use or conditions – this test, performed by the customer, would be a form of validation testing.

This brings up an interesting debate about reliability….we can strive to validate product reliability in the development and verification process with reliability test methods. We can reasonably duplicate (and accelerate) the customer’s environment, product use cases and other factors affecting reliability…perhaps not entirely, however. True validation of product reliability might only really occur on the fielded product.

Throughout the entire systems/validation engineering process, we are ensuring we are building the right product (validation) and building the product right (verification).

Hopefully, this article series helps define and highlights the importance of the systems/validation engineering function.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply