A few weeks ago I met with Cesar de Leon who is a pipeline safety expert (http://www.pipelinesafetyconsultant.com) – he worked at the DOT Office of Pipeline Safety for over 23 years and currently resides in Boerne, Texas. Cesar was telling me about legal and technical issues arising in the field of natural gas pipelines from existing regulations… I will discuss these issues in greater details in latter posts. Before getting into current issues, I would like you to read the following guest post from Cesar that provides a brief overview of pipeline integrity management plan.

Integrity Management Plan

The Integrity Management Plan (IMP) for natural gas transmission pipelines was issued in December 15, 2003 (68 FR 69817). It is the most extensive regulation to the gas pipeline regulations in 49 CFR Part 192 since the gas pipeline regulations were originally issued in 1968.

The following is a very simplified discussion of steps involved in complying with the requirements in Subpart O.

Identify High Consequence Areas (HCA)

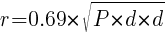

HCA are typically areas of high population density (including Class 3 and 4 locations as defined in 192.5) as well as based on a Potential Impact Radius (PIR) calculated as follows:

,

,

where,

r = radius, in feet;

P = MAOP, in pounds per square inch; and

d = nominal pipe diameter, in inches.

Any building within a PIR containing 20 or more buildings intended for human occupancy is classified as HCA. Similarly identified sites (such as beaches, playgrounds, recreational facilities, buildings, community centers, churches) that fall within PIR are HCA.

Perform Threat Identification and Risk Assessment

Identify threats to pipeline segments in HCA and assess risks. At the end of this task, each pipeline segment is given a numerical score based on the estimated risk.

Develop a Baseline Assessment Plan

Pipeline operators should develop a schedule for performing pipe integrity assessments over the 10-year period. Results from prior risk assessment results are used to prioritize the integrity projects. The worst 50% must be assessed by December 17, 2007 and the other 50% by December 17, 2012. Along with the schedule, the pipeline operator must select the method of integrity assessment.

Integrity Assessment

The integrity of the pipe segments is assessed according to the schedule and methods identified in the Baseline Assessment Plan. There are three primary assessment methods:

- Inline inspection – e.g. smart pig

- Pressure test – the pipe is hydro tested to at least one and one half its normal operating pressure

- Direct Assessment – is used to address threats of external corrosion internal corrosion, and stress corrosion cracking.

For pipelines operating at or above 50% SMYS, the internal inspection, pressure test, or direct assessment must be conducted every 10 years. The reassessment intervals are 15 years for pipelines operating from 30% SMYS to 50% SMYS, and 20 years if the pipeline is operating below 30% SMYS. A confirmatory direct assessment as described in §192.931 must be conducted by year 7 in a 10-year interval and years 7 and 14 of a 15-year interval.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply