RRP 051 Thermography with Paul Goodbody

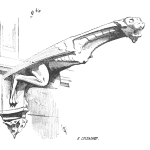

On this week’s episode, I welcome Paul Goodbody on to the show. Paul is a level 3 thermographer and the IRISS. We talk about what we can detect using infrared cameras, how often we should take readings and Paul gives us some top tips for using thermography as a predictive maintenance tool.

I have released my own reliability, maintenance and asset management coaching, consulting and professional services offerings, check out robsreliability.com for more information and if I can help you become a better reliability engineer or your company achieve it’s reliability goals, please email me at robsreliabilityproject@gmail.com. I look forward to working with you.

In addition, if your company sells products or services to maintenance, reliability and asset management professionals and you would be interested in having your message spread to engaged industry professionals, tell your marketing manager about Rob’s Reliability Project. There are advertising options available from appearing on the podcast, video/picture content to having an ad read on the show. If one of those appeals to your company, email me at robsreliabilityproject@gmail.com to get more information.

If you haven’t signed up for my weekly reliability newsletter with extra exclusive content, go to http://robsreliability.com/email-list/ and sign up!

Follow Paul Goodbody on LinkedIn – https://www.linkedin.com/in/paul-goodbody-b8689a42/

Check out IRISS – https://www.iriss.com/

Follow Rob’s Reliability Project on LinkedIn – https://www.linkedin.com/company/robsreliabilityproject/

Follow Rob’s Reliability Project on Facebook – https://www.facebook.com/robsreliabilityproject/

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.