Guest Post by John Ayers (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

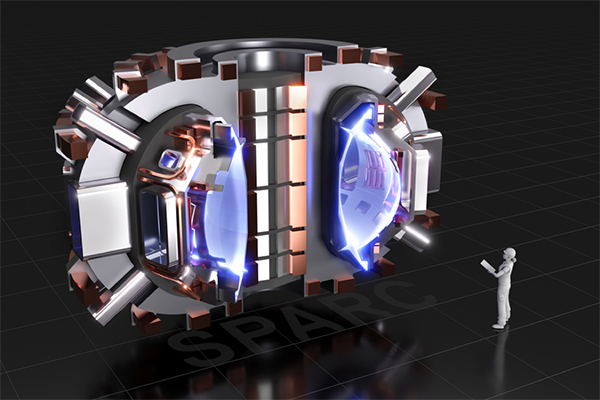

New superconducting magnet breaks magnetic field strength records, paving the way for practical, commercial, carbon-free power fusion energy. MIT and U.S. startup company Commonwealth Fusion Systems (CFS) led the project. This test paves the way for a demonstration device to show a plasma can be created and contained that generates more energy than it consumes. The demonstration device is expected to be completed in 2025. The hope is that in the future there will be thousands of fusion plants powering clean electric grids around the world helping to save the planet.

This paper describes the fusion process and the new superconducting magnet. It also provides some history of fusion energy, superconducting magnets, and my background in fusion energy.

Fusion Process

“Fusion is the process that powers the sun: the merger of two small atoms to make a larger one, releasing prodigious amounts of energy. But the process requires temperatures far beyond what any solid material could withstand. To capture the sun’s power source here on Earth, what’s needed is a way of capturing and containing something that hot — 100,000,000 degrees or more — by suspending it in a way that prevents it from coming into contact with anything solid. That’s done through intense magnetic fields, which form a kind of invisible bottle to contain the hot swirling soup of protons and electrons, called a plasma. Because the particles have an electric charge, they are strongly controlled by the magnetic fields. The most widely used configuration for containing them is a donut-shaped device called a Tokamak. Most of these devices have produced their magnetic fields using conventional electromagnets made of copper. The latest and largest version under construction in France, named International Thermonuclear Experimental Reactor (ITER), uses what are known as low-temperature superconductors.”[i]

The figure below shows a cross section of a Tokamak device.

Superconducting Cable

“The innovative technology described in the paper is a superconducting cable that conducts fusion energy. Electricity with no resistance or heat generation and that will not degrade under extreme mechanical, electrical, and thermal conditions. Branded VIPER (an acronymic feat that stands for Vacuum Pressure Impregnated, Insulated, Partially-transposed, Extruded, and Roll-formed). It consists of commercially produced thin steel tapes coated with High Throughput Screening (HTS) compound (yttrium-barium-copper-oxide) that are packaged into an assembly of copper and steel components to form the cable. Cryogenic coolant, such as supercritical helium, can flow easily through the cable to remove heat and keep the cable cold even under challenging conditions.”[1]

Some History of Fusion Energy

During the late 1970s, when Jimmy Carter was President, there was a severe oil shortage resulting in long lines at the gas pumps. U.S. Public law 96-386, signed into law by President Carter on October 12, 1980, authorized accelerated research, development, and demonstration of an operating prototype fusion power plant. It was never funded because a large surplus of oil was found? When Ronald Regan was elected President,he moved the energy R & D budget to the Defense Department to support his goal of building 600 Navy ships.

My Background in Fusion Energy

In 1979, I worked for a company located in Waltham, Massachusetts, that was hired by the Princeton Physics Lavatory (PPL) to design the magnetic bottle that would contain plasma in the Tokamak fusion machine they were building. I was sent to PPL for three years (1979-1981) to support the effort. My company produced superconducting wire, superconducting magnets for MRI machines, and other magnet services. The company was staffed with mostly MIT PhDs and was considered the best magnetic design company in the country at the time.

During my first year at PPL, I was assigned to the Princeton Large Torus (PLT) to design and implement improvements. At the time, it was the only fusion experimental machine working in the world. The Princeton Physics Team measured the temperature inside the plasma of the PLT at 80 million degrees Celsius when I was there. This achievement reverberated around the world because half the physics community at the thought the plasma could not sustain a temperature beyond 40 million degrees Celsius without collapsing and stopping the fusion reaction. The PLT experiment proved a fusion reactor was feasible.

My last two years were spent working on the Tokamak Fusion Test Reactor (TFTR) experiment. It went operational in 1982 and operated until 1997. At one point, it reached the break-even point (energy-in equals energy-out).

Summary

Research and development of fusion energy has been going on for decades in the U.S and around the world. In the 1970’s physicists were responsible for the budget to develop fusion energy. I learned while working for three years at PPL that physicists have a thirst for knowledge but not for developing a product. When called before congress for a status on fusion energy they were asked-is it ready to turn over to the engineers? The answer was always no. We need more devices to complete our research they were told. MIT and startup company Commonwealth Fusion Systems (CFS) engineered the new break through.

There are still many challenges ahead. For example, developing a design that allows for safe, reliable, environmental controlled, sustained operation. Other challenges will be economic. How do you design these power plants to be cost effective to build, operate, and maintain?

Fusion energy is within our grasp this decade. The plants will be made in America, create hundreds of thousands of jobs, and supply energy that can save our planet. It will also make electric forms of transportation feasible. Solar and wind have their place, but cannot provide the on-demand baseload power needed for vehicle charging stations while powering America’s homes and industries.

Bio:

Currently John Ayers is an author, writer, and consultant. He authored a book entitled Project Risk Management. It went on sale on Amazon in August 2019. He authored a second book entitled How to Get a Project Management Job: Future of Work. It is on sale on Amazon. The first is a text book that includes all of the technical information you will need to become a Project Manager (PM). The second book shows you how to get a PM job. Between the two, you have the secret sauce to succeed. There are links to both books on his website. https://projectriskmanagement.info/He has presented numerous Webinars on project risk management to PMI. He writes columns on project risk management for CERM (certified enterprise risk management). John also writes blogs for Association for Project Management (APM) in the UK. He has conducted a podcast on project risk management. John has published numerous papers on project risk management and project management on LinkedIn.

John earned a BS in Mechanical Engineering and MS in Engineering Management from Northeastern University. He has extensive experience with commercial and U.S. DOD companies. He is a member of the Project Management Institute (PMI. John has managed numerous large high technical development programs worth in excessive of $100M. He has extensive subcontract management experience domestically and foreign. John has held a number of positions over his career including: Director of Programs; Director of Operations; Program Manager; Project Engineer; Engineering Manager; and Design Engineer. He has experience with: design; manufacturing; test; integration; subcontract management; contracts; project management; risk management; and quality control. John is a certified six sigma specialist, and certified to level 2 Earned Value Management (EVM). Go to his website above to find links to his books on Amazon and numerous papers.

[1] MIT-Commonwealth Fusion Systems Demonstration of New Superconducting Cable is a Key Step on the High-field Path to Compact Fusion.

Leda Zimmerman | Plasma Science and Fusion Center

Publication Date:

October 13, 2020

[i] New Superconducting Magnet Breaks Magnetic Field Strength Records, Paving the Way for Practical, Commercial, Carbon-free Power.

David Chandler | MIT News Office

Publication Date:

September 8, 2021

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply