Fatigue is a common degradation and failure mechanism. It involves localized, permanent damage to metals exposed to cyclic stress. The stress can be uniaxial, bending, or torsional resulting from a variety of sources including an applied force, vibration, acceleration and deceleration, and differences in thermal expansion between mating components exposed to heating and cooling cycles. Localized means the damage is confined to a small portion of a component or joint.

The reason fatigue is sometimes unexpected is because the nominal stress acting on a component or joint is less than its yield strength. However, at a fatigue crack initiation site, the stress is greater than the nominal stress due to the presence of a stress concentration. More on this later.

Three requirements

There are three requirements for fatigue to occur:

- Cyclic stress

- The stress must be tensile

- The local stress must exceed the metal’s yield strength

Three stages

Fracture due to fatigue consists of three stages:

- Stage 1: Crack initiation. Microcracks less than 0.001 mm long form as the material cycles between the upper and lower stress. As the cycling continues the microcracks grow and coalesce, forming one or more larger cracks.

- Stage 2: Crack growth. The larger cracks grow into the material. As the cracks grow the nominal stress on the uncracked portion of the metal increases.

- Stage 3: Finally, when a critical amount of the cross section has cracked, the remaining uncracked material cannot bear the load and fractures by overload.

Fracture surface

This is a diagram of a fracture surface where a crack started by fatigue. The crack started at the component’s surface. Once the crack formed it grew with each successive stress cycle. Finally, the crack grew so large that the uncracked material could not support the load, and it cracked during a single stress cycle.

In many cases, beachmarks are present on the fracture surface that can be seen visually or with a low-power microscope. Beachmarks start at the crack origin and expand in the direction of crack growth and are helpful for identifying the crack origin.

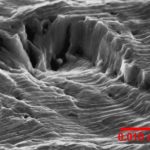

This scanning electron image shows the fracture surface of an aluminum component. The striations are a result of the fatigue crack growing with each stress cycle. Each striation formed during a stress cycle, thus indicating the amount the crack grew with each stress cycle. Not all fatigue failures have striations on the fracture surface.

Stress concentrations

Fatigue damage occurs even though the nominal stress on a metal is less than its yield strength. Stress concentrations cause an increase of the stress, resulting in a localized stress that exceeds the yield strength of the material. Stress concentrations include notches, identification markings, and metal defects (non-metallic inclusions, voids, laps).

It is possible for a fatigue crack to form in a metal with a smooth surface and no apparent stress concentrations. However, more cycles are required to initiate a crack in such a metal compared to the same metal with an apparent stress concentration.

Factors that influence fatigue life

The fatigue life of a component or joint is often expressed as the number of cycles to failure, which is equal to the sum of the number of cycles to initiate a crack and the number of cycles for the crack to grow to failure. In some cases, failure is when a crack grows to a pre-determined length, at which point the component or sub-assembly is removed from service. In other cases, failure is when a component or joint fails, and the failure is often unexpected.

Several design, material, and fabrication factors influence component and joint fatigue life, including the following:

- Mechanical design features that are stress concentrators

- Alloy strength

- Non-metallic inclusions and manufacturing defects

- Surface residual stress

- Surface roughness

- Metal fracture toughness

These factors and approaches to improve fatigue resistance will be discussed in more detail in future articles.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Hi Michael,

I enjoy reading your articles.I am a mechanical engineer who is involved in Failure analysis of components mainly associated with the oil and gas producing,refining and petrochemical industries.

I will appreciate if I can laise with you

From time to time re such failures.

Hi Zaid,

I’m glad to hear you like the articles. I’d be happy to help out, though it’ll have to be on a consulting basis.

Mike