When processes trend naturally due to tool wear, traditional control charting methods fail. The trend (which is expected) results in inappropriate “out-of-control” signals. Control charts should detect unexpected changes in the process. If the trend is expected, we do not want to be alerted to this trend. If no accommodation is made for this trend, the chart will incorrectly produce “out-of-control” signals. [Read more…]

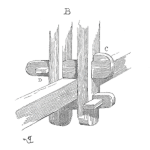

Lubrication is often overlooked in organizations. Why it is overlooked, I am unsure. Maybe it is because it is considered to be a basic job, given to the apprentice, or it is just too simple to not to do it correctly.

Lubrication is often overlooked in organizations. Why it is overlooked, I am unsure. Maybe it is because it is considered to be a basic job, given to the apprentice, or it is just too simple to not to do it correctly.