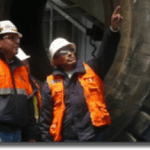

Don’t run centrifugal pumps on the end of the curve. Pumps are designed and selected to operate near their highest efficiency point.

If they operate at the right-hand end of the pump curve the likelihood of cavitation increases.

Keywords: suction pressure, flow velocity, vapor pressure, duty point. [Read more…]