Written instructions make it clear.

Written directions given to maintenance tradesmen to reduce the chance of making an error and to reduce time spent looking for information are called job procedures or job instructions. [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Mike Sondalini Leave a Comment

Written instructions make it clear.

Written directions given to maintenance tradesmen to reduce the chance of making an error and to reduce time spent looking for information are called job procedures or job instructions. [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Paul Kostek (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

You’ve completed your project’s Risk Management Plan and now you can move forward with project execution because all of the project’s risks have been identified what can go wrong? Well plenty. It’s easy to get caught up in weekly (daily) reviews of the identified risks, tracking status (are the boxes going green, yellow, oh no red?). [Read more…]

by Fred Schenkelberg 2 Comments

Sometimes the reaction rate of a process relies on two stresses. For chemical reactions temperature seems to influence the rate of the reaction. Yet, other stresses such as humidity or voltage may also play a significant role.

H. Eyring suggested a model that assumes the contribution of each stress on the reaction rate is independent thus one could multiple the respective stress contributions to the rate of reaction.

The Erying model provides a means to account for the contributions of temperature and another stress when modeling the time to failure of select failure mechanisms. [Read more…]

by Anne Meixner Leave a Comment

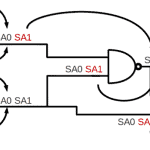

Semiconductor Integrated Circuits (ICs) can have millions of digital circuits which can translate to billions of transistors.

I know these numbers can be intimidating, but I assure you the challenges of testing ICs started in the mid-late 1970’s. Lots of effort has been put into Electronic Design Automation (EDA) systems and Design for Test (DFT) techniques to manage the development and application of digital circuit testing.

In the beginning these software programs and DFT techniques used the Stuck at Fault Model. [Read more…]

by Dennis Craggs Leave a Comment

Here is an example of a common engineering development task. A design engineer needed a life test plan for a switch verification in a safety system. We jointly developed a plan by taking a system view of the component function, considered corporate and regulatory requirements, customized it to the supplier’s test capabilities, executed the plan, and made design changes to remove product defects. [Read more…]

by Fred Schenkelberg Leave a Comment

Your peers, team mates, and management want to understand your writing. They want to quickly get your point, find supporting information, and take action.

As a reliability engineer, you write proposals, plans, and reports. You write problem statements, failure analysis findings, recommended process improvements, and much more.

You write to document a process or plan. More often you write to encourage others to take action.

Writing clear, concise missives the incite action is a hallmark of a good reliability engineer. You are doing technical writing.

You can learn to write well. [Read more…]

by Doug Plucknette Leave a Comment

The following article came about from an on-line conversation I had with a follower who responded to an article I had written on the differences between Leaders and Managers. Her hope was that someday soon someone in a leadership position at her company would recognize the harm her boss was causing and how miserable he had made the lives of those who worked for him.

So as promised here is my take on working for a bully boss!

If you’re lucky you only work for one in your lifetime. [Read more…]

Imagine an operation in which there are no lost time accidents, OEE is increasing and there is a plan to address the skills shortage. These sites do exist and chances are they using procedure based maintenance. Procedure Based Maintenance is simply having all maintenance activities documented in a procedure. These procedures are then followed step by step when conducting breakdown, corrective and preventative maintenance. [Read more…]

by Adam Bahret Leave a Comment

Many product programs ( actually all) are on a tight schedule. When Accelerated Life Testing (ALT) get’s it’s place in the process it is another mouth to feed. ALT is not a short process. Each round of testing typically takes weeks, and the results may drive design changes that prescribe additional testing. It is common to want to get the ALT process going as quickly as possible. In this haste the primary wear-out failure modes and it’s driving stresses are confidently stated, a model is created, and the test is started.

by Greg Hutchins Leave a Comment

Guest Post by Paul Kostek (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

What’s the risk of not addressing a risk? What happens on a project when a risk is identified and not addressed/mitigated? There may be reasons not to correct it, e.g low probability of occurrence and minimal impact, but how do we document and track this decision? And if we’re delaying an implementation how do we insure the risk is addressed at a later date, e.g. next version release? How do we insure that if an audit takes place the project team can clearly explain the reasons for the decision? Is this even acceptable? [Read more…]

by Mike Sondalini Leave a Comment

What readers will learn in this article.

Couplings are used between shafts to connect them so power can be transmitted and to allow for axial expansion. Shafts can either be aligned or intentionally inclined at an angle to each other. When at an angle a universal joint is used to connect the shafts. When aligned a shaft coupling is fitted. [Read more…]

by Fred Schenkelberg 1 Comment

I may have the name, waterfall, used incorrectly here.

Years ago I learned from a former Apple reliability group manager how to organize reliability and environmental related testing where samples cascade through a sequence of stress conditions and evaluations. He called it waterfall testing. [Read more…]

by Anne Meixner Leave a Comment

Depending upon the type of engineer you ask the word test evokes a different notion of goals and expectations.

Engineers who work on the design of semiconductors test that their designs meet the specifications.

This can be done pre-silicon and naturally verified in-depth on silicon.

Engineers concerned with manufacturing of a product test to find defects and to verify performance.

Similar approaches can be taken by both engineers though there exist differences in the amount of time. To be cost effective, a manufacturing test must be completed in as short a time as possible. Let’s continue to compare and contrast design validation with manufacturing test. [Read more…]

by Fred Schenkelberg Leave a Comment

The role of a reliability engineer is to support the other engineers and managers as they make decisions concerning reliability.

Our ability may be well honed and effective. Or it may be fumbling or annoying. It is our ability to communicate along with our technical ability that determine our ability to influence well.

We may do analysis or testing. We follow up on failures and evaluate suppliers. What we actually are doing is influencing decisions. [Read more…]

by Doug Plucknette Leave a Comment

When people first begin to learn about Reliability Centered Maintenance and methodologies like RCM Blitz, they get excited about the potential results that can come from performing a RCM analysis and implementing the resulting tasks. Shortly after completing their RCM Training some begin to understand that good RCM takes leadership, structure and discipline, others begin to think of ways to shortcut the process. [Read more…]