Can you find this common error in detection ranking in the intermediate problem in this article? In the advanced problem, the topic of an in-service detection scale will challenge the most experienced readers.

Articles

Find all articles across all article series listed in reverse chronological order.

Defining Precision Maintenance

Ask 10 people to tell you what Precision Maintenance means. While some will use a few of the same words or give a few similar examples of what they think Precision Maintenance is you are going to get 10 different answers.

While few would argue the importance of Precision Maintenance, I find it interesting that in the world that offers Certifications in Asset Management and Equipment Reliability (CRE, CRL, CMRP) you won’t find an agreed-on definition of what Precision Maintenance means. [Read more…]

Learning from A Failure

Why Failing Can Be Good and What You Can Take Away from It.

Regardless of how good a maintenance & reliability program is set up and managed, there will be failures. This is partly due to the maintenance program itself, where the focus is on the consequences of the failures, not the failures itself. This approach allows most organizations to manage large facilities will a minimum of staff and cost.

But what should happen when something does fail? Should we just carry on as usual since we avoided the consequences? Absolutely not. When a failure occurs, we need to learn from it and improve the maintenance & reliability program. Yet, many organizations address failures by implementing a PM routine. This is not the right approach. Remember only 11% of failures are age-related. Adding these PM routines to the program will cause a collapse of the program from too much work, not to mention the maintenance induced failures that result from it.

So what should happen? The failure should be analyzed and actions implemented to reduce the chance of the failure occurring again.

[Read more…]

Oil — How Clean Does it Have to Be?

Clean, dry oil can extend equipment life between failure up to 8 – 10 times the normal operating life. Timken, the bearing manufacturer, reports that reducing water levels from 100 ppm (parts per million) to 25 ppm increases bearing life 2 times. British hydraulics research indicates that if solids contamination with particles larger than 5 microns (0.005 mm or 0.0002”) is reduced from the range of 5,000 – 10,000 particles per milliliter of oil to 160 – 320 particles, the machine life is increased 5 times. [Read more…]

Wicked Problems

Guest Post by Joseph Paris (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Wicked Problems

There are all manner of problems (being an optimist, I rather use the term “challenge”) that we face each and every day.

Most of these challenges are simple enough: what’s for dinner this eve; is there traffic on the highway that is going to impede my progress; do I have any clean underwear, and so on. Some challenges are more complex; how are we going to meet our production schedule; my primary vendor has failed and I need to bring a replacement on-line; which automobile or house should I purchase and what are the financing options, etc…

Then there are “wicked problems”. [Read more…]

The “Mid-Life Crisis” Use-Case

When a product has broad usage profiles how do you create one for a test protocol. Do you select the easiest? Obviously not because there is risk of a high failure rate from poor evaluation. Do you select the hardest use-case? You could but there is the risk you spend too much time and money making the product overly robust for most of your customers.

In these cases where test time is limited and only a single use case can be tested I create a “Composite” use-case. It captures many of the different types of stresses from the full list of use-cases but keeps an accumulated stress on the design that represents at least 98% of the customers.

Equipment Reliability Depends On Understanding Failure Modes!

One of the curses of Reliability Centered Maintenance and Root Cause Analysis is a great Facilitator makes the process look easy. So easy in fact that after watching a good facilitator lead one event we’d like to believe we could jump right up and facilitate the next one with no training or assistance. In Mentoring RCM Blitz™ facilitators during the certification process we work to perfect 2 dozen skills with the hope of turning out great facilitators. The skill we typically spend the most time working on is writing failure modes.

A 2-Step Process to Improve Plant Performance

A Simple Q&A Can Reap Improved Performance in Any Activity in Maintenance.

A failure has just occurred on a critical asset in your facility. The result was 2 hours of lost production, but it could have been worse. The last time that the equipment failure occurred it took 5 hours to repair. Why was the failure repaired in less than half the time than the previous occurrence? How can we ensure that we learn from this failure and the team’s performance to improve the plant performance?

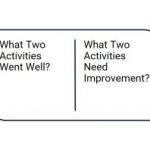

I remember reading about a simple philosophy quite a few years ago (although I can’t remember who stated it, so I apologize that I cannot provide a reference), about a simple analysis that can be applied to any maintenance activity to improve performance. This analysis is call the 2 Up / 2 Down analysis.

The 2 Up / 2 Down analysis is quite simple and involves asking two questions.

[Read more…]

The Project Approval Committee

A project approval committee can be an effective way to enable business decision-making and ensure projects are successful.

Committees may be known as a project review or steering committee; however, consider the following (proposed) objectives as follows:

- Approve new projects (and project resources)

- Approve project phase (phase gate) completion

- Approve project go-forward plans (including resources)

- Cancel projects that no longer make business sense

- Prevent rogue/unapproved projects from consuming resources

- Direct / redirect projects to complete key tasks or deliverables before moving forward

- Enforce project management planning and execution

Reducing Wear in Abrasive Conditions

Abrasion is the removal of material from a surface by the movement of material across its surface. The factors affecting abrasive wear are the surface properties of the item being worn away, the abrasive properties of the material moving across the surface and the characteristics of motion. [Read more…]

Recovery: Least Understood Element of Business Continuity Lifecycle

Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

The post-crisis recovery phase is one of the least addressed in planning, training and simulations. This is an area that, if not properly managed, can cost financially, reputationally and operationally. Communications, internal and external are, at best, misjudged. Guidelines for recovery are lacking and most entities lose focus when it comes to discussing recovery operations. It may be that recovery is one of the most complicated of the lifecycle elements and that no two recoveries are going to follow the same pattern.

However, the recovery process can be segmented into manageable bits that can be undertaken using a project management approach. [Read more…]

Cardboard and Duct Tape: Lessons in Engineering, Leadership and Life

As part of the 35th Anniversary of the Governor’s Scholars Program in Kentucky, I was invited to participate in their Alumni Day at Northern Kentucky University. So naturally, I shared with this year’s Scholars what my experience taught me about engineering leadership and life!

Below are the slides and lessons learned that I shared. [Read more…]

Statement of Work Fundamentals

In my last article, we reviewed a proposed Product Life Cycle process, which starts with a “Define” phase. In the “Define” phase, we are defining the project as well as the product.

We previously discussed the ‘technical leg’ of this process with the market analysis, identifying customer needs, product requirements, verification and validation, etc. [Read more…]

Stages of Awakening

A common progression (stages of awakening) for an organization that has a minimal application of reliability tools to one that is large market holder with the right reliable product is often like this

Stage 1) “Reliability” testing is mostly re-labeled verification and validation testing. It measures if the design does what it is supposed to do at the end of the program. Tests are executed with the intent of passing, not learning about the product or it’s performance under variability. The organization experiences a large field failure surge due a single or multiple issues. The pain of this experience in dollars, market image, and lost resource through “recovery phase” awakens them to the high ROI of incorporating reliability tools early and throughout the product development process

at the end of the program. Tests are executed with the intent of passing, not learning about the product or it’s performance under variability. The organization experiences a large field failure surge due a single or multiple issues. The pain of this experience in dollars, market image, and lost resource through “recovery phase” awakens them to the high ROI of incorporating reliability tools early and throughout the product development process

Process Capability VII – Confidence Limits

Introduction

In prior articles on process capability, sample statistics and SPC statistics were assumed to be population parameters and ignored sampling variability. This article reviews the analytic methods that can be used to develop confidence bounds on the process capability indices.

$-P_p-$ Index

The Pp index calculation requires an estimate of the parameter σ. The index is calculated as: