What you will learn from this article.

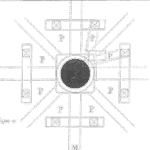

- Glued plastic pipes must have the joints prepared before gluing.

- Some plastic is joined with glue while others are solvent joined.

- Glued joints do not bond with the plastic but must be ‘hooked’ to it.

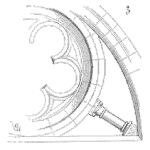

- Install thrust brackets if large glued pipes change direction sharply.

Some plastics can be joined with glues or cements. One of the most common of these is PVC. PVC can be either unplasticised (uPVC) or chlorinated (cPVC). Some plastics can be dissolved and chemically bonded together. ABS plastic is such a plastic. [Read more…]