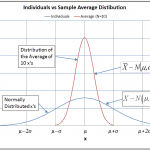

Test To Bogy Sample Sizes

Introduction

Reliability verification is a fundamental stage in the product development process. It is common for engineers to run a test to bogy (TTB). What sample size is required for a TTB?

Reliability Testing

Reliability is the probability of a part successfully functions under specified life, duty cycle and environmental conditions. Many functions are specified during the design process. Each reliability test will be focused to validate a specific function. The targeted verification level depends on the criticality of the function and potential failure modes. The life could be specified as a count of cycles, an operating time, or perhaps a mileage or mileage equivalent. The duty cycle is a description of how the device is used. Environmental stresses are generally included in the test.