Introduction

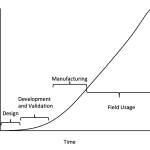

Automotive Electronic parts are qualified before usage in serial production. When product quality and reliability are poor, then assembly problems, high warranty costs, poor service, and recalls occur. The OEM’s and suppliers followed different qualification plans. Ford, GM, and Chrysler and large parts suppliers started the Automotive Electronics Council (AEC) in the 1990’s, with the mission of defining a suite of common qualification tests.

The first qualification standard was Q100, which defined stress tests for electronic components containing integrated circuits. These components are in every electronic control module, some sensors, entertainment systems, safety systems, and, in the future, autonomous driving systems.