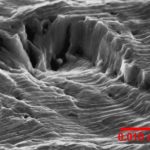

The bathtub curve is one of the most famous graphical representations in reliability. It shows the typical trend of failure rate over time (Figure 1). This curve can be divided into three parts corresponding to decreasing, constant and increasing failure rate.

High but decreasing failure rate in the first part of the curve (1) indicates products defective or prone to fail due to manufacturing or design issues. The middle section (2) is characterized by low and constant failure rate. Failures in this phase are caused by unpredictable external events like flatting tire or power surge causing electronic failures. The right-hand side of the bathtub curve (3) shows increasing failure rate. In this stage, failures occur due to wear-out damage mechanisms such as fatigue, creep, ageing, wear and corrosion.

[Read more…]