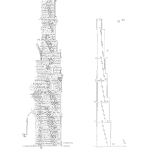

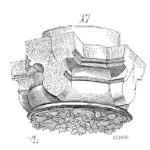

Fibreglass construction and repair. Fibreglass is a glass fibre reinforced plastic composite with excellent chemical resistance properties. Its physical properties, selection of resins and glass, method of construction and fabrication and peculiar repair requirements must be appreciated when using this material.

Keywords: laminate, backing layer, structural layer, corrosion barrier, crack repair, winding angle. [Read more…]