As I’m writing this, it’s December of 2019 and you should be putting the final touches on your reliability plan for 2020 before the holidays.

What should you include in your reliability plan? [Read more…]

Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Robert Kalwarowsky Leave a Comment

As I’m writing this, it’s December of 2019 and you should be putting the final touches on your reliability plan for 2020 before the holidays.

What should you include in your reliability plan? [Read more…]

by James Reyes-Picknell Leave a Comment

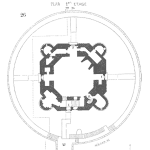

By: James Reyes-Picknell & Uri Wittenberg. The Four Sustainability Stages of the Conscious Asset Framework™ comprise 3 building blocks each. Each of these blocks will be reviewed and customized to fit each individual organization’s unique needs.

Let’s take a closer and more detailed look at each of the four stages and their elements. [Read more…]

by Alex Williams Leave a Comment

There’s no denying the power of the Internet of Things (IoT) on our everyday lives. Connected devices provide us with the convenience we’ve become so accustomed to. Take the Amazon Echo, for example. It’s much easier to ask Alexa to add an item to your grocery list than it is to write it down. But IoT technology doesn’t just impact consumers, it’s transforming the way companies do business. And integrating IoT with CMMS software opens up a world of new possibilities for maintenance management professionals.

The use of CMMS (computerized maintenance management systems) software to streamline maintenance operations and reduce costs has existed for many years. However, new capabilities within CMMS software have been realized thanks to IoT technology. Aside from convenience, the IoT provides greater reliability through its vast data connections. Going back to the Amazon Echo example, you can’t always rely on yourself to remember to bring a written grocery list with you to the store. But you can rely on a list generated by a cloud-based voice service and access it through your mobile device. Data stored within the cloud works to the same advantage for maintenance professionals—it gives them the ability to simplify and improve many tasks.

by Robert Kalwarowsky 10 Comments

I’ve had a nagging feeling that I needed to write about this topic for a while and I haven’t for fear of judgment. In honor of a mental health campaign in Edmonton titled 11 of Us after the statistic that 11 Edmontonians that attempt or die by suicide each day) and my core values of honesty, impact and service, here it is, my struggle with mental health.

June 4th, 2010 – This day should have been the biggest moment in my life up to that point. I walked across the stage and graduated from MIT. Coincidentally, it was also my 22nd birthday. I remember feeling void, questioning what’s next for me. Up until recently, those feelings never left. [Read more…]

Physical Asset Management has received a lot of attention in recent years within the asset intensive industries e.g. oil/gas, energy, utilities, process & manufacturing. On one hand, the release of PAS 55 & its subsequent follow-up by ISO 55000 has brought Physical Asset Management within limelight & on the other hand it has created an ambiguity for many Maintenance practitioners. [Read more…]

by James Reyes-Picknell Leave a Comment

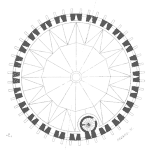

By: James Reyes-Picknell & Uri Wittenberg. In figure 2 below, it should be clear that The Conscious Asset Framework™ is general in nature. It is what we want to achieve but how do we get there?

Few of us are fans of cookie-cutter, one-size-fits-all, approaches and methodologies. They just don’t work without some sort of tailoring. Some consulting firms have rigid approaches and they won’t vary from them. Others claim to have no approach, but in reality most simply haven’t taken the time to articulate one. Most, including many “experts”, do use some guiding methodology or model even if they can’t (or won’t) describe it clearly. [Read more…]

by Robert Kalwarowsky Leave a Comment

In last week’s blog, I discussed 3 advantages to using AI in reliability. This week, I’ll give you 3 mistakes that people can make. [Read more…]

by Bryan Christiansen Leave a Comment

With industry statistics like the one from a joint study by the Wall Street Journal and Emerson, it’s no wonder that more manufacturers are looking for ways to proactively handle unplanned machine downtime. Among several issues discussed, the study states that unplanned downtime costs manufacturers about $50 billion per year. Furthermore, it mentions that outdated maintenance programs waste resources and potentially expose staff to higher safety risks.

by Alex Williams Leave a Comment

Preventive maintenance software can provide a number of benefits for organizations. From increasing labor productivity to extending equipment life, these benefits can significantly impact a company’s bottom line. However, outcomes of preventive maintenance software largely depend on the software program selected. Consider these essential functions when selecting preventive maintenance software:

At the heart of any computerized maintenance management system (CMMS) is the ability to schedule preventive maintenance tasks. Since preventive maintenance is essentially planning ahead, a CMMS should allow you to create a maintenance schedule for each piece of equipment. Within each schedule, a complete set of required inspections and manufacturer’s guidelines should be adhered to. Comprehensive maintenance schedules help ensure all equipment operates in peak condition and helps prevent unplanned repairs.

by James Reyes-Picknell Leave a Comment

By: James Reyes-Picknell & Uri Wittenberg. Many companies struggle with improvement efforts of all sorts. The ISO standards on Asset Management have sparked a great deal of interest that goes beyond just the maintenance and engineering communities.

CFOs understand the potential benefits of good asset care and good life cycle asset decisions – they want the financial performance, improved revenues from dependable production capacity, reductions in CAPEX and OPEX from higher reliability, increased standardization and design for maintainability as well as operability. [Read more…]

by Robert Kalwarowsky 3 Comments

Last week, I appeared on the “Ask the Experts” panel webinar with my friends at UpKeep – you can listen to the recording here. The first question to the panel was about the advantages and disadvantages of using AI for predictive maintenance. [Read more…]

by Robert Kalwarowsky Leave a Comment

Regular preventive maintenance (PM) makes up a large portion of many maintenance programs and, sometimes, we don’t get the results we want out of all that maintenance. Reliability professionals should evaluate their PMs to ensure effectiveness both from a reliability & cost perspective. [Read more…]

With the growing trend of Internet of Things (IoT), Artificial Intelligence (AI) and Data Science in Industrial Asset Management domain; I just wonder whether the Plant Engineers will still be keeping tab on the ‘Operating Context’ of their assets to extract real value from these revolutionary technologies or will just rush like lemmings to adopt them. [Read more…]

by Alex Williams Leave a Comment

The ability to make smarter asset management decisions is one of the main benefits of implementing computerized maintenance management software (CMMS). And the driving forces behind that ability are the reporting and dashboard features. Data mining is arguably the most important CMMS feature of all—it’s certainly a feature you should assess carefully when comparing software options. The CMMS reporting feature helps organizations accomplish the following:

Tracking key performance indicators (KPIs), or quantifiable metrics that reflect performance, allows maintenance managers to measure success. Mean Time Between Failure (MTBF) is a common KPI reported on within CMMS software. It reflects the amount of time lapsed between occurrences of asset failure, enabling maintenance staff to pinpoint problem assets. For example, a low MTBF for a specific piece of equipment could indicate there’s an underlying issue. Reporting KPI measurements such as these help maintenance managers spot potential trends leading to equipment breakdown and lags in production.

by Robert Kalwarowsky Leave a Comment

Over the last month, I’ve hired a coach to help me improve so I can improve and, more importantly, be happier. In one of my latest sessions, my coach said the goal for every day is “progression not perfection”. The concept being that perfection is unattainable and if we judge ourselves on perfection, we’re always going to be unhappy. [Read more…]