Ships Don’t Last Like They Used To

Robert G. Albion was a notable historian of maritime affairs. He taught at Princeton and Harvard, and was one of the US Navy’s chief historians during World War II. In one of his books, Albion examined how timber management in Britain affected naval shipbuilding and maintenance policies.

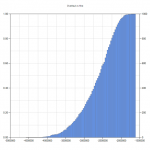

In the late 1700s, the British Empire was more dependent on the navy for power projection, home defense, and security of maritime trade. In the age of sail, the average ship life was between 10 and 20 years. In the 17th century, British naval ships lasted 25-30 years. Albion found their average service life to be only 13 years in 1771. By 1792, service life fell to 12 years. In the Napoleonic period, the lifespan fell to only 8 years.

“The ‘life’ or duration of a ship was reckoned from the date of her launching to the time when her condition necessitated repairs as costly as the construction of a new ship.” The British determined service life by a basic level of repair analysis.