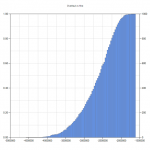

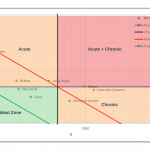

The management of spare parts and inventories is all about balance between the cost of stocking the parts and the costs and risks of not having them when they are required.

As a consultancy owner, one of the most overlooked issues I see in Industrial operations is the management of spare parts. I don’t have enough fingers, toes and limbs to count how many times I’ve heard the phrase ” The machine is down because we’re waiting on spare parts”.

I see this phrase normalised so often that people don’t bat an eye and have accepted it as the norm- a lot of maintenance professionals don’t focus on the effective management of this area . I think this is overlooked because it requires MATH to calculate- and just like poetry, most people hate math. [Read more…]