Measles Chart Basics

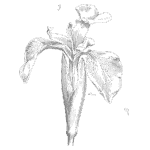

The clever Dr. John Snow mapped cholera cases during the epidemic of 1854 on a street map of the area. This type of mapping now called a measles chart, or defect location check sheet, or defect map, is useful when exploring the effect of location data.

The name measles chart may have come from the habit of using an image of drawing of a product and adding small red dots to signify defect locations.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.