With Paul Crocker

A recorded webinar on how to educate your leadership team on the value of asset management.

[Read more…]Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by George Williams Leave a Comment

A recorded webinar on how to educate your leadership team on the value of asset management.

[Read more…]by André-Michel Ferrari Leave a Comment

A Root Cause Analysis (RCA) is a structured approach to identifying the underlying factors that result in the unwanted/unexpected outcomes of chronic or sporadic events. It is a highly methodic and rigorous process. And highlights what assets, systems or behaviors need to be modified in order to to limit or eliminate the recurrence of similar outcomes. The fundamental driver is to address, correct or mitigate the root causes that lead to the unwanted event rather than addressing the symptoms. Bob Latino, a renowned RCA expert, summarizes this concept as “the establishing of logically complete, evidence based, tightly coupled chains of factors from the least acceptable consequences to the deepest significant underlying causes.”

[Read more…]by Fred Schenkelberg 13 Comments

Over 20 years ago the Assistant Secretary of the Army directed the Army to not use MIL HBK 217 in a request for proposals, even for guidance. Exceptions, by waiver only.

217 is still around and routinely called out. That is a lot of waivers.

Why is 217 and other parts count database prediction packages still in use? Let’s explore the memo a bit more, plus ponder what is maintaining the popularity of 217 and ilk.

[Read more…]

Project managers are challenged by creating, implementing, and maintaining workflows, Standard Operating Procedures (SOPs), and standard instructions. The same applies to maintenance and reliability professionals who develop preventative maintenance (PMs) and job plans. Knowing the difference between each type is the first step. Then, the number of steps in each of these often depends on the audience’s experience, the task’s complexity, and preference. It’s most important for project managers to find the sweet spot.

[Read more…]by Semion Gengrinovich Leave a Comment

Accelerated Life Testing (ALT) on subcomponents and durability testing for whole products are two strategies used to assess the reliability of products. ALT involves subjecting a product to conditions beyond its normal service parameters to uncover faults and potential failure modes in a short time, allowing engineers to make predictions about its service life and maintenance intervals. On the other hand, durability testing for whole products involves testing the entire product under normal operating conditions to assess its long-term reliability and performance.

[Read more…]by Steven Wachs Leave a Comment

Stability studies are used to understand and model the degradation of key product characteristics over time. They are often used to determine the product’s shelf life (the length of time a product may be stored without becoming unfit for use or consumption).

Shelf-Life studies should identify the potential “failure modes” and how they will assessed/ measured. Examples of characteristics that are measured often include appearance attributes, texture, taste, microbial counts, and product effectiveness/performance.

[Read more…]by Mike Sondalini Leave a Comment

In 1987 the ISO9000 quality management series was launched; superseding the earlier BS5750 document. It has progressed from its initial product quality focus to its now customer satisfaction focus. During all its life the question of the usefulness of ISO9001 to business growth and performance has dogged it. The greatest fault of ISO9001 is its lack in setting quality performance. It mistakenly asks companies to select their own quality standards to work to. That is its single greatest problem—the lack of quality benchmarks and is the reason why it is common to hear managers call ISO 9001 a waste of time. But if you address ‘quality’ correctly in your ISO 9001 quality management system you can turn your company into a world-class performer within three years.

[Read more…]by Greg Hutchins Leave a Comment

The Focus of driver safety is on preventing accidents and implementing the necessary protocols to control risk across commercial fleets, but crashes do happen, so, the question I ask is are fleets doing enough to help drivers when they are involved in a collision?

Globally an estimated that 1.3 million people die every year due to a road traffic collision, in addition there are between 20-50 million more suffering non-fatal injuries. These often result in life-changing injuries, which have far-reaching consequences for both family and friends. Research has shown that up to 40% of people will be trapped in their vehicles following a collision. [Read more…]

by Nancy Regan Leave a Comment

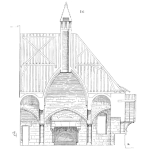

Frank Lloyd Wright was a master architect, known for designing structures that harmonized with their environment. Just as he had a clear vision for his designs, the original architects of Reliability Centered Maintenance (RCM) had a specific intent for how the process should be carried out. Unfortunately, RCM is often implemented in ways that stray from these foundational principles. In this video, recorded at the Frank Lloyd Wright House in Florence, Alabama, I explore the parallels between Wright’s architectural genius and the importance of adhering to the true principles of RCM. Learn how SAE JA1011 can guide you in evaluating and ensuring that your RCM process is done as its creators intended—leading to more effective, transformative results. Join me as we bridge the worlds of architecture and reliability.

[Read more…]by Hemant Urdhwareshe Leave a Comment

Dear friends, we are happy to release this video on Acceptance Sampling plans for Attributes. In the video, Hemant Urdhwareshe explains how to select appropriate sample size using Sampling Plans such as MIL-STd-105E, ANSI/ASQ Z1.4, IS 2500 Part-1 (or ISO2959 -1). The video also explains interpretation of Operating Characteristics from the standards and in Microsoft Excel. Additionally, Hemant also illustrates how to generate a Sampling Plan in Minitab software.

[Read more…]by Miguel Pengel Leave a Comment

A Weibull analysis is one of the most versatile tools in a Reliability Engineer’s toolbox. I have received many requests to start summarizing some of my articles and case studies into quick and easy PDF references for distribution.

[Read more…]

Reliability professionals are trusted advisors. Being a trusted advisor to a person making the biggest career decision is an enormous job—as is making a good, big decision. Where most advisors lose the “trust” in “trusted advisor” is when they mix the roles of “advisor” with “decision maker.” Advisors and analysts must first be true to their data and information. How that information is used is not something you control. These are three reasons a reliability professional should not care about the decision.

[Read more…]by Semion Gengrinovich Leave a Comment

Using highly accelerated stress screening to identify supplier defects before the product is shipped saves time and money.

[Read more…]by Steven Wachs Leave a Comment

In my 30-year career as an Industrial Statistics consultant, I have frequently been told by clients that they have performed Design of Experiments (DOEs), to try and resolve design or manufacturing issues. What has become clear is that many engineers and scientists apply a rather liberal definition to DOE and include any type of experimentation in what they deem to be “DOE”.

The reality is, simplistic or haphazard “experiments” rarely are effective in solving problems, especially complex ones. Statistically based DOE provides several advantages over more simplistic approaches such “trial and error” or “one-factor-at-a-time” experimentation. These advantages include:

Each of these advantages are discussed in a bit more detail below.

[Read more…]by Greg Hutchins Leave a Comment

This is a story about project reporting, and its importance to project management. No matter how many or how few reports there are, it’s the report that provides the information that managers need to make decisions. It’s also not about the glut or the dearth though, it’s about the quality of the content and timing of delivery that can make all the difference between right or wrong decisions, and a project’s overall outcome.

So, if you are sitting comfortably then I’ll begin.

[Read more…] Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.