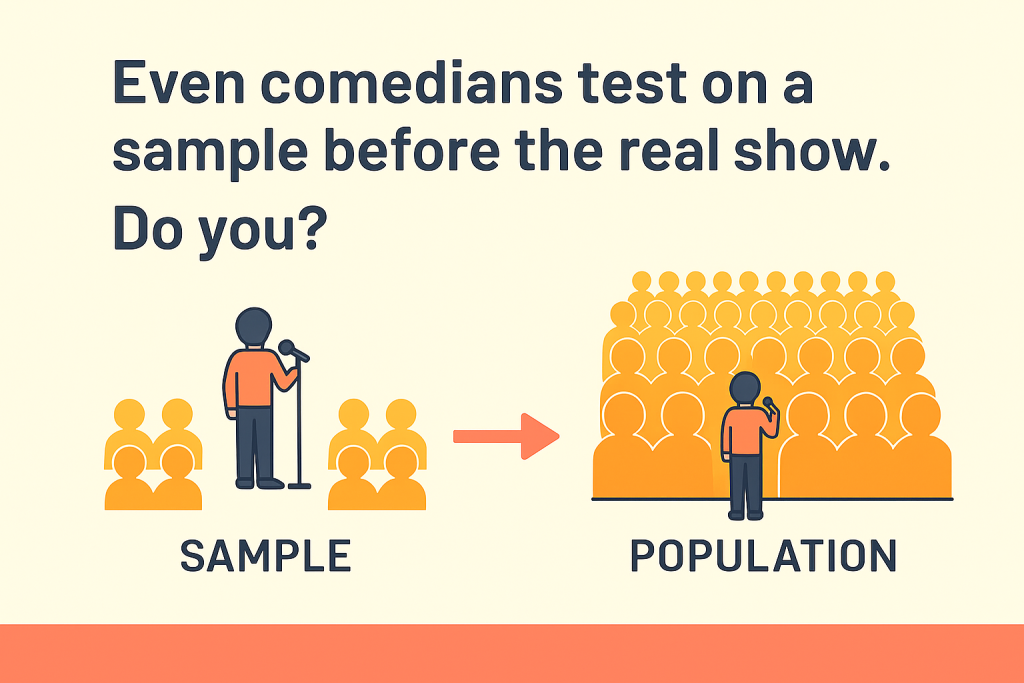

We were chatting with some coworkers about stand-up comedians, and someone mentioned that even the most popular comedians try out their new material in small venues before doing a big show for a larger audience. They do this to collect feedback and fine-tune their performance before reaching thousands of people across different cities.

My reliability engineering brain immediately reacted: “This means even stand-up comedians understand the importance of sampling.” They perform a small-scale version of their show to understand how the audience reacts. Based on that feedback, they decide whether the show is ready for a wider audience. In other words, they want to estimate the population’s reaction based on a sample. To me, this is a perfect example of statistical sampling.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.