Demographic shifts in the workforce have given us “younger” companies with less experience and little guidance other than the way we were “raised”. Has the way you were raised left you with a mindset that is getting in your own way?

[Read more…]Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by James Reyes-Picknell Leave a Comment

Demographic shifts in the workforce have given us “younger” companies with less experience and little guidance other than the way we were “raised”. Has the way you were raised left you with a mindset that is getting in your own way?

[Read more…]by Mike Sondalini Leave a Comment

Nuclear power stations, nuclear warships and air traffic control centers are renowned amongst industry world-wide for their high-reliability performance. Here is a reliability-based model of how they do it. Your organisation can too.

Keywords: control of human error, failure prevention, defect elimination, accuracy-controlled enterprise, error-proofing

My brother-in-law, who worked for Japan Airlines (JAL) at the time, tells a story of watching Japanese aircraft maintenance technicians overhaul a JAL airplane jet engine. He tells this story because it is so unusual. During his visit to the maintenance hanger he was enthralled by the extraordinary maintenance procedure that the JAL technicians followed.

[Read more…]by Michael Keer Leave a Comment

In the previous chapter, how markets and global needs can impact your product was discussed.

In this chapter the differences between agile Hardware and Agile Software are explored to allow you understand how to apply agile techniques to a hardware development workflow.

The desire to gain a competitive advantage by releasing products faster has driven the widespread adoption of agile software methodologies. More recently, a push to apply agile techniques into the hardware development process has yielded mixed results, This is because electronic hardware products cannot be tested until complete subassemblies are built, and so important modifications to the product realization process are necessary.

[Read more…]by Joe Anderson Leave a Comment

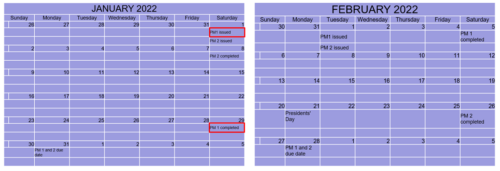

Time-based PM variation.

by Nancy Regan Leave a Comment

The First Maintenance Lesson I Ever Learned—and How It Applies to Reliability Today

In today’s storytime, I’m sharing the first maintenance lesson I ever learned, back when I was eleven years old and eager to change the oil in my father’s car. As you’ll see, this experience taught me a valuable lesson about quality assurance and accountability—and it reveals one of the biggest mistakes many Reliability Teams make today.

[Read more…]

In Part 1 of Beyond the Numbers, I reflected on why Human Factors matter in reliability engineering and how the human element of the system can be overlooked by traditional hardware-focussed approaches.

This article explores how Human Factors principles can be integrated into traditional reliability analyses such as Reliability Block Diagrams (RBDs), Fault Tree Analysis (FTA) and Failure Mode, Effects and Criticality Analysis (FMECA) and without reinventing the wheel or introducing additional complexity.

The short answer is that we are already doing much of this implicitly. Applying Human Factors principles makes those assumptions explicit and therefore visible, challengeable and open to improvement. [Read more…]

Think about the greatest risk you have encountered in the past five years. Maybe it was related to physical injury or serious sickness. It could be related to the mental health of a family member. Natural disasters or career changes are obvious ones. In fact, you can probably think of more than one great risk you have recently experienced.

Now, what is the definition of risk? In technical sessions and my workshops, well-educated business professionals struggle with the terminology. It usually takes two to three minutes for someone to arrive at their definition. The sad news is that there are about as many definitions as there are well-educated people in the room.

[Read more…]by Fred Schenkelberg Leave a Comment

Just when I thought we had experienced every possible MTBF definition confusion, here’s another.

This one is courtesy of the thread concerning the impact on reliability when adding redundancy to a system. [Read more…]

by Semion Gengrinovich 1 Comment

Yes, reliability testing can be done in parallel with design validation (DV). This approach has both advantages and disadvantages, which are important to consider in the context of product development and testing.

by Greg Hutchins Leave a Comment

Since the 1990s, organisations have attempted to improve safety culture. They have tried top-down approaches, with senior management making statements about how important safety is. They have tried bottom-up hearts and minds programs, encouraging workers to work safely, and stop if a job can’t be done safely. There have been great strides, and examples of success, such as the UK 2012 Olympic development.

However, many safety culture programs stall after some initial improvements. Senior managers have invested in the program. Workers on the frontline want to be safer and healthier. Sometimes the obstacles come from the middle managers and supervisors, who are invested in existing ways of doing things. For a busy manager there just isn’t time to get ahead with improvement programs while they are doing the day-to-day supervision and management tasks.

[Read more…]by Mike Sondalini Leave a Comment

First develop maintenance strategy—what you want to achieve with your equipment maintenance, why it is necessary, and how to do it.

Then turn strategy into the plans to maintain production asset reliability with the equipment maintenance program.

Often maintenance managers and maintenance engineers are asked to develop a maintenance strategy for their plant and equipment. They need to develop a document. In it you explain how you are going to use the least plant and equipment maintenance expenditure and efforts to ensure the necessary production performance from your production plant and equipment.

[Read more…]by Larry George Leave a Comment

The Apple Computer Reliability Department manager, Wayne Smith, told me (circa 1991), “We make sure Apple doesn’t sell a product that doesn’t work,” (by in-house product tests during design phase). (I worked in Apple’s Service Department.) Testing helps, but real, age-specific reliability is determined in the field, in the hands of customers, in their environments. Companies could benefit from using age-specific, field reliability to eliminate waste, improve customer satisfaction, and reduce uncertainty. The Field Reliability Applications Award is a clone of the Malcolm Baldrige National Quality Award modified to quantify reliability maturity. The field reliability applications evaluation in this article supplements Fred’s podcast on “Reliability Maturity” [Schenkelberg].

[Read more…]by Miguel Pengel Leave a Comment

It’s 2 AM. Your SAG mill gearbox just failed. The plant is down, losing $95,000 every hour. You call the warehouse: “Do we have a spare?”

That answer could mean the difference between a 4-hour repair and a 4-week nightmare waiting for an emergency shipment from overseas. The frustrating thing is, someone made a decision months or years ago about whether to stock that gearbox. They either got it right, or they didn’t. Tonight you find out which.

This scenario plays out daily across mining and processing operations worldwide, and most organizations don’t know they’ve got it wrong until that phone call comes. They’re either sitting on millions in dusty inventory that’ll never be used, or they’re one failure away from catastrophe. The sweet spot in the middle is surprisingly hard to find. [Read more…]

by Nancy Regan Leave a Comment

True or False? Is an Reliability Centered Maintenance (RCM) Analysis Ever Really Complete?

In this video, I tackle a common question: Once you’ve completed a Reliability Centered Maintenance (RCM) analysis, is there any need to revisit it? The answer is False! RCM is a living program that should be reviewed whenever key circumstances change, like operational tempo, the operating environment, or even what’s required from the equipment.

[Read more…]by Hemant Urdhwareshe Leave a Comment

Dear friends, wish you all a very happy 2026! After a long gap, I am happy to release my 104th video! As we all know, statistical analysis software is becoming quite expensive to buy and maintain! On this background, it is good to know that there is a powerful open-source statistical analysis software ‘JASP’ which is completely free! While JASP is free, its capabilities are excellent and can be a good substitute for a commercial software! I thought of sharing some information about this free open-source software JASP! In future, I intend to demonstrate how to use JASP for performing statistical analyses in few more videos. Your feedback is welcome!

[Read more…] Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.