What people need are practical business solutions. They do not need science projects – or efforts only for the sake of learning. [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Perry Parendo Leave a Comment

What people need are practical business solutions. They do not need science projects – or efforts only for the sake of learning. [Read more…]

by Robert Allen Leave a Comment

Previous articles have covered a proposed waterfall product development phase/gate process. This article will compare and contrast waterfall with Agile product development, especially with respect to the front-end of the process.

Let’s start with a proposed waterfall product development phase/gate process. (The process below implies a hardware product, however, it can be considered any waterfall process for now.)

by Greg Hutchins Leave a Comment

Enterprise Risk Management (ERM) is a relatively new concept. It is a top down approach to business system management and execution. It is designed to identify potential events and risks that can impact the organization. There are 3 levels to ERM. These are: Enterprise Level; Program/Project Level; and Product level. This paper explains the differences between the program and project level. [Read more…]

by Mike Sondalini Leave a Comment

One method to clean particles from a liquid or gas is to pass it through a filter. The filter is a screen that traps and holds the contaminants on its surface while allowing the fluid to twist its way past the build-up and screen. The screen can be used until the back- pressure from the collected contaminants choke it so severely that the fluid flow falls drastically. At that point the screen must be cleaned. This article explains how membrane and leaf filtration processes work and the critical factors that produce successful filtration results. [Read more…]

by James Kovacevic Leave a Comment

There has been much discussion (and often debate) around the P-F curve. The P-F curve illustrates the relationship between the warning signs that are detectable by various technology or methods and the progression of the failure. What is often not discussed and overlooked, is what happens before the equipment starts to deteriorate.

There has been much discussion (and often debate) around the P-F curve. The P-F curve illustrates the relationship between the warning signs that are detectable by various technology or methods and the progression of the failure. What is often not discussed and overlooked, is what happens before the equipment starts to deteriorate.

If the ultimate goal of an organization is to be proactive and ensure equipment uptime, wouldn’t the organization want to prevent the equipment from failing in the first place and not catch it after it has already started to fail? [Read more…]

KISS, “Keep It Simple, Stupid” is a US Navy principle from the 1960’s advocating that systems function best if they are kept simple rather than made complicated and that unnecessary complexity should be avoided.

In our politically correct world ‘stupid’ is often taken as an insult and ‘keep it short and simple’ or ‘small and simple’ is often substituted. ‘Stupid’ is not an insult, it’s a warning! It takes a bright person to keep things simple, particularly when it’s easier to have a complex mess under the guise of sophistication. Projects inevitably become complicated as they develop which increases the risk of potential failings.

Keeping things simple can improve the chances of success and simplicity is best achieved during the project planning before execution takes place; or after wild enthusiasm has waned. [Read more…]

In some process situations, mechanical level sensors are the best choice for the environment or are stipulated by law (as in boilers). To operate these devices requires the physical contact of the process being measured. They provide solid indisputable proof that a process condition has been achieved. Provided the mechanical mechanism is connected and working properly, these devices provide the most believable proof that a level in a vessel, tank or silo is actually what the instrument is saying it is. [Read more…]

by Adam Bahret Leave a Comment

I introduced my new program tool “Program Risk Effects Analysis” (PREA) at the RAMS Conference in Orlando this week. It’s a great tool to assist in accessing if program schedule or resource should accommodate found design risk from testing or analysis.

-Adam

by Carl S. Carlson Leave a Comment

FMEA teams should agree to the ground rules that guide the analysis and the underlying assumptions that impact the entire FMEA. Failure to do so will add complexity and confusion to the resulting FMEA, and waste people’s time. Don’t miss this important step in FMEA preparation.

“Your assumptions are your windows on the world. Scrub them off every once in a while, or the light won’t come in.” Isaac Asimov

by Doug Plucknette Leave a Comment

In past articles I have often referenced Dr. Aubrey Daniels and the use of Behavioral Psychology and Analysis in the workplace. In the late 1980’s I was fortunate enough to attend a 2-week course in Performance Management put on by Dr. Daniels and two of his associates where we learned the importance of measuring behaviors as opposed to results. To say that this course was enlightening would be an understatement as it was in this class I first learned why we need to measure leading indicators as opposed to results. [Read more…]

by Perry Parendo Leave a Comment

In sports, the mantra of “Respect all but fear none” is used by many coaches. This same philosophy is appropriate for New Product Development. Respect the design or process – nothing is simple. Yet, do not fear new things. A healthy respect for trying new things. This is how we coach and how we consult! [Read more…]

by Greg Hutchins Leave a Comment

This story is about risk at the enterprise program/project level. Design is based on primarily requirements and assumptions. Meeting requirements is usually achievable if they are complete and clear. Soft or poorly written requirements are the source of cost and schedule growth for many projects. Assumptions made during the analysis or design phase if wrong are also a source of poor project performance. This story is one example of a bad assumption. [Read more…]

by Mike Sondalini Leave a Comment

A computerised maintenance management system (CMMS) is the maintenance department’s most important tool. It provides insight into the behaviour of the facility’s individual assets, i.e. the plant and equipment. For a CMMS to be of use it must be used as an information ‘bank’ that can be investigated. There are 9 really good reasons to use a CMMS. And each one of them alone makes a CMMS worth having. [Read more…]

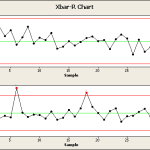

Many companies use SPC to control their manufacturing and assembly processes. Other companies use 100% inspection and some companies do nothing. How can one choose between these three alternatives?

To make a rational choice, some questions need to be answered.

by Perry Parendo Leave a Comment

We provide business solutions. How can we prove it? This video provides the basis for our experiences with results. [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.