This failure occurred on a turbine driven boiler feedwater pump (TDBFP) at a fossil fuel power plant. The pump in question is an outboard boiler feed pump. Plant is operating normally when unexpectedly pump shuts down and causes a forced outage.

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Robert (Bob) J. Latino Leave a Comment

This failure occurred on a turbine driven boiler feedwater pump (TDBFP) at a fossil fuel power plant. The pump in question is an outboard boiler feed pump. Plant is operating normally when unexpectedly pump shuts down and causes a forced outage.

What does the word statistics bring to mind when you hear it? Horrible high school classes that you sat through wondering why do I need this stuff? Complex math problems what were almost impossible to figure out? Or is it nonsense that is only used in political polls?

What does the word statistics bring to mind when you hear it? Horrible high school classes that you sat through wondering why do I need this stuff? Complex math problems what were almost impossible to figure out? Or is it nonsense that is only used in political polls?

Statistics are used in every aspect of Reliability Engineering. So if you don’t have a good relationship with statistics, I highly recommend that you are starting investing time in building your knowledge in statistics. [Read more…]

by James Reyes-Picknell Leave a Comment

Most of us wouldn’t argue that if you can measure it, you can improve it. Performance measures do indeed drive results, both good and bad. Knowing where you are now and what you want to achieve by some point in the future do help you to outline your path towards your objective. Once you know your path, you then need a way to make sure you are still on it. And once you’ve past way-points, you also need to know that what you’ve achieved so far, continues to be sustained.

by Greg Hutchins Leave a Comment

In several pieces for Insights, I have discussed the decline of ISO 9001 certifications, the internal and financial problems ASQ is experiencing and the implications for the quality profession. Recently I was on the ASQ website. There are several references to Quality 4.0. This article will look at Quality 4.0 and its implications for the Quality Profession. It will also provide an update on ASQ’s financial problems and the possibility it will declare bankruptcy.

by Steven Wachs Leave a Comment

We are ready to learn how to analyze the data collected during the experiment. This is the most exciting part of DOE! We will cover the analysis in this article as well as the next several articles.

The following are the main steps to perform during the analysis:

by Carl S. Carlson Leave a Comment

“Team leadership is the secret that makes common people achieve uncommon results.” – Ifeanyi Onuoha

One of the key factors for successful application of FMEAs is skillful facilitation of FMEA teams. The skills needed for excellent facilitation are different from the skills needed to be a good FMEA team member. [Read more…]

by Christopher Jackson Leave a Comment

Organizations are all about ‘success.’ Being ‘successful.’ Which can many different things to many different people. ‘Success’ is not simply the ‘antithesis of failure.’ One could argue that ‘mediocrity’ in many cases is accepted as the antithesis of ‘failure.’ ‘Mediocrity’ is hardly the same as ‘success.’

Organizational success means that a lot of different people need to be doing lots of very different, but very important things. And this often means things that can go unnoticed. The ‘one percenters.’ Getting things done right the first time.

by Robert (Bob) J. Latino Leave a Comment

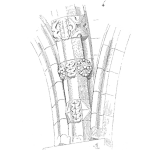

This is a failed shaft that came out of a pump in a paper mill. The pump was only in service for about a month before it failed unexpectedly.

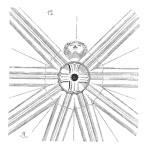

From the top view above, identify the type of failure pattern that you see from the fractured surface(s). If you need more info to make your assessment, just ask.

by James Reyes-Picknell Leave a Comment

Materials management for maintenance purposes is often a big mess. When I visit operations (doesn’t matter what industry) I often hear complaints from maintainers that they cannot get the parts they need, when they need them. Sometimes, their supply chain (warehouse, inventory, and purchasing management) are indeed a mess, but more often than not maintenance planning is also a mess, and there is usually (almost always) a lack of integration between planning and supply chain.

by Greg Hutchins Leave a Comment

The initial journey to create “sustained success” got off to a difficult start in 1987 when the intent was for quality managers to implement ISO 9004 followed by ISO 9001 for certification purposes. ISO 9004 was viewed as being associated with TQM. The extra work that was needed to fulfill TQM led organizations to use ISO 9001:1987 alone to certify their processes.

by Ray Harkins Leave a Comment

“Everything’s computerized now. The backyard mechanic is a thing of the past!”, I recall my father declaring more than 20 years ago while leaning over the open hood of my mother’s Ford Windstar. He was referring to the relative simplicity of repairing the largely mechanical systems in automobiles from the 1950’s and 60’s versus those of the early 2000’s that were equipped with digital sensors and a central processor. Of course, today’s plug-in EV’s, advanced driver assist systems, 360-degree cameras, and “guardians” like General Motors’ OnStar make my mom’s old minivan look like an Anglia in comparison.

by Steven Wachs Leave a Comment

When applied properly, SPC provides manufacturers a proven method to increase profitability and achieve a deeper understanding of their processes.. Additionally, SPC can prevent problems—saving companies money that would have been lost in scrap, rework, warranty, litigation, and market share decline. A key factor in obtaining these SPC benefits is the proper deployment of control charts. Correctly designed control charts identify significant changes to a process. These can be changes that are still within specification, but are statistically different than where the process was previously running. By identifying the changes, personnel can determine what caused the change and potentially improve the process or prevent the production of inferior products. [Read more…]

by George Williams Leave a Comment

We will create a reorder point analysis file from scratch with simple CMMS data as our starting point. Learn how to create a file which will update automatically each time CMMS data is updated.

[Read more…]by Larry George Leave a Comment

The ASQ Reliability Division (RD), copyrighted the 2003 monograph “Credible Reliability Prediction” (CRP) but lost all copies circa 2014. I pestered the RD to let me republish CRP, because people asked “How do I make credible reliability predictions?” Copyright reversion to authors is accepted practice when a publisher no longer supports a document.

[Read more…]

The new deepwater expansion joint design meets company requirements for factors of safety but cannot comply with ASME Section VIII load factors. How does the OEM engineering manager proceed?

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.