A short discussion about goals and the losses they create.

[Read more…]Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by George Williams Leave a Comment

by Ray Harkins Leave a Comment

Most successful engineers, analysts, programmers, and other types of makers of products and services will, at some point in their career, encounter a crossroads where they can either continue making, engineering, and programming, or they can begin managing those who do.

[Read more…]by Carl S. Carlson Leave a Comment

“Seek first to understand, then to be understood.” – Stephen Covey

A good listener tries to understand thoroughly what the other person is saying. In the end the listener may disagree sharply. However, before voicing disagreement, the active listener wants to know exactly what the other person is saying and why. [Read more…]

by Carl S. Carlson Leave a Comment

“Seek first to understand, then to be understood.” – Stephen Covey

A good listener tries to understand thoroughly what the other person is saying. In the end the listener may disagree sharply. However, before voicing disagreement, the active listener wants to know exactly what the other person is saying and why. [Read more…]

by Doug Plucknette Leave a Comment

According to the US Bureau of Labor Statistics data released in December of 2020, 5,333 Americans died on the job in 2019. While 40% of these deaths were cause by transportation incidents and 15% were attributed to workplace violence, nearly 2400 on the job deaths were a direct result of one of the following causes;

· Falls, trips or slips

· Contact with objects or equipment

· Exposure to harmful substances or environment

· Fire or explosion

[Read more…]by Robert (Bob) J. Latino Leave a Comment

I have been very involved recently with ongoing LI discussions with respected and noted experts in the Safety community, revolving around the perceptions those in Safety have of Reliability, and vice-versa.

In Safety today, there are ‘new’ approaches emerging being lead by noted Safety researchers like Sidney Dekker, Erik Hollnagel and Todd Conklin. Such ‘new’ approaches are being labeled Safety Differently, Safety II, Human and Organizational Performance (HOP), Resilience Engineering and a few more.

[Read more…]by James Kovacevic Leave a Comment

by Michael Pfeifer, Ph.D., P.E. Leave a Comment

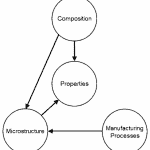

In the previous article I discussed product design in general and the importance of leveraging materials engineering to design components that meet performance and reliability requirements at low cost. Both component form and materials can and should be engineered to optimize a component’s design.

In this article I discuss a component design process that explicitly includes materials engineering considerations. This process involves consideration of all design requirements and cost. Not just designing for reliability. That’s where selecting materials gets tricky – having to consider different sets of requirements and design for ease of component fabrication and joining.

by James Reyes-Picknell Leave a Comment

Asset Performance management is a vast expansion on the highly successful concepts of Condition Monitoring and Condition Based Maintenance.

Recently we co-hosted a webinar on the leverage of Industry 4.0 technologies such as the IIoT and AI to show what is really involved in Asset Performance Management. Here is a recording of that video webinar.

[Read more…]by Greg Hutchins Leave a Comment

This is not an article about an endangered species plundered to near extinction as trophies for big game hunters or being poached for its aphrodisiacal ivory or describing a mythical elephant’s graveyard…it’s about those metaphorical elephants that frequent rooms in political corridors of power, boardroom suites and project offices around the World. Although these elephants are known to exist they are either not immediately recognised or conveniently avoided.

[Read more…]by Mike Sondalini Leave a Comment

Making great choices that get world class reliability for your company is what you do with Plant Wellness Way Enterprise Asset Management methodology.

by George Williams Leave a Comment

IEC 60601-1 says… Estimate the probability per time pe of an electrical failure and of an oxygen leak po. Determine the accepted probability of dangerous failures [fire] per time r. Calculate the inspection time interval tc = r/(0.5*pe*po).

A friend asked, “What’s the 0.5 for? It doesn’t account for the fire event sequence: leak before spark.” I posted correction tc = r/((po/(po+pe))*pe*po) and notified the IEC committee which acknowledged, “We’ll consider your suggestion for edition 4.”

[An earlier, shorter version of this article on www.LinkedIn.com, July 5, 2018. This version describes an inspection-time and risk-analysis template.]

[Read more…]by Robert (Bob) J. Latino Leave a Comment

There has been an ongoing debate for decades as to whether or not the use of pre-existing logic for conducting Root Cause Analyses helps or hinders the analysis results. Does the use of such pre-existing logic expand the thinking of the team members or does it lead the team to pre-determined conclusions and away from other conclusions not considered in the pre-existing logic? We will explore the fine line between these opposing views and see if there is a middle ground for consensus. [Read more…]

by James Kovacevic Leave a Comment

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.