Absolutely not! That is a big misconception of the process. You get to decide how broadly or how narrowly you apply Reliability Centered Maintenance.

Read moreYour Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Nancy Regan Leave a Comment

Absolutely not! That is a big misconception of the process. You get to decide how broadly or how narrowly you apply Reliability Centered Maintenance.

Read moreby Karl Burnett Leave a Comment

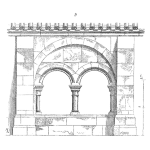

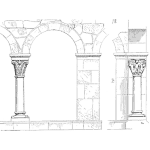

British writers often marvelled at the quality and longevity of Roman roads, wondering how modern engineers and governments could hope to imitate their success. The fascination with Roman roads continues, and an excellent overview by Richard Brushi is available on Medium.com.

[Read more…]by James Reyes-Picknell 1 Comment

I approach problems with computer systems in a fairly critical way, but I am not anti-CMMS/EAM technology. I am, however, anti-waste. All too often I see a lot of time, effort, and money going into technology that simply doesn’t provide a return on the investment. When it comes to Maintenance data – it is often problematic and unfit for many of its intended purposes. Aside from helping to administer work orders, these systems often provide little business value. Does a small saving in administrative cost and time really justify the millions often spent on these systems?

[Read more…]by Mike Sondalini Leave a Comment

A robust Maintenance Planning and Scheduling Process uses a Scheduled Work Crew capacity planned days ahead with planned jobs. And it has a small Quick Response Crew of people capable to handle any random job.

A great Maintenance Planning and Scheduling Process design separates reactive work from jobs that can be planned and scheduled. This article explains how to re-engineer a maintenance planning and scheduling process to handle reactive and planned jobs.

[Read more…]

[Read more…]We are facing difficulty in developing a definition of Critical Spare Part Inventory. No one is able to define it in its true essence. The situation is further confused with the difference to strategic spare parts. Any guideline or standard where we can find it ?

In the past, every Plant Manager had their own definition of Critical Inventory which changed with time. In optimization of Inventory, the first step is to establish a definition of Inventory considering all factors like production loss, redundancy, safety hazard, failure frequency, and of course, the lead time? Still I am stuck in this phase. I cannot progress, and don’t know what to do 1st, 2nd, and so forth to proceed further in this journey?

by Mike Sondalini Leave a Comment

In some industries, 40% of maintenance repairs result from original equipment manufacturing failures. And up to 35% of maintenance is traceable to design engineering mistakes. That totals 75% of maintenance costs during operation can be from prior life cycle process blunders

To get utmost operating plant and equipment reliability, you need to purposefully design and build your business processes to guarantee maximum reliability from each and every phase of the asset life cycle

[Read more…]by Nancy Regan Leave a Comment

Hi Everyone. Are you struggling to implement Reliability Centered Maintenance (RCM) because you need buy-in from people? Well, if that’s the case, I have a solution for you. And we’re going to take our lead from these gorgeous daffodils.

Daffodils are my all-time favorite flower. I’m a sucker for them: (1) Because they look so happy! (2) You can always rely on them. At the same time every year, the daffodils come up. And there is a technique you can rely on to get the buy-in you need from management and other people within your organization to implement Reliability Centered Maintenance and it is this.

[Read more…]by George Williams Leave a Comment

George Williams, CEO of ReliabilityX, giving us the quick run down on using Infrared Thermography technology and its benefits.

[Read more…]by James Reyes-Picknell Leave a Comment

Recently, we ran a two-week-long survey about training. It asked two questions and here are the results:

For training of your workforce, which do you prefer?

Nearly 3000 viewed the question and 70 answered:

by Mike Sondalini Leave a Comment

The 20th Century saw maintenance strategy evolve from corrective, predictive and preventive maintenance to reliability maximization. During the 21st century maintenance will disappear and be replaced with risk-free equipment operation where no failures occur. The first steps taken by LRS Consultants toward building risk-free businesses and riskless operational processes was the invention of the Plant Wellness Way “system-of-reliability” methodology.

[Read more…]by George Williams Leave a Comment

George Williams, CEO of ReliabilityX, telling us why we should use Ultrasound Technology

[Read more…]by Mike Sondalini Leave a Comment

Split And Clamped Mounting Hub For Shaft Attachments. For speedy and easy maintenance it is best to use a clamped hub to mount attachments to shafts when possible. This article presents a conceptual design of a split hub bolted and clamped to a shaft. The required attachment is then mounted to the removable hub.

[Read more…]by Nancy Regan Leave a Comment

Are you procrastinating on bringing a goal alive?

If you think dumping a few gallons of water in your oil reservoir would be bad for your rotating equipment, consider the consequences that “striving for perfection” has on your happiness and productivity.

I call it the Prison of Perfection and it’s wicked. It’s where our goals go to die 👿.

by Karl Burnett Leave a Comment

How did railroads handle depreciation, repair, and fixed asset life-cycles in the mid 19th Century?

They were experienced in design, construction, project management and business.

They planned for maintenance and for repair.

They knew about wear mechanisms from aggressive operation and thought it was management’s role to contain this.

They shared data and used it. They gathered data from handwritten records, making spreadsheets, graphs, and KPIs by hand.

[Read more…]by James Reyes-Picknell Leave a Comment

Jim and Richard explore the world of parts, what it takes to keep a proper storeroom, and why forecasting demand is crucial for it.

[Read more…] Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.